Language

Views: 0 Author: Site Editor Publish Time: 2025-09-16 Origin: Site

Blow molding machines are vital in modern manufacturing. They help create hollow plastic products, from water bottles to automotive parts. But many businesses struggle to understand how much these machines cost. The price depends on several factors, including machine type, size, brand, and additional features.

In this guide, we’ll break down the cost of blow molding machines in 2025, explore types, compare with injection molding, and give tips to make smart investment decisions.

The cost of a blow molding machine is not fixed. It varies depending on multiple factors. Here’s what to consider:

There are three main types: extrusion, injection, and stretch blow molding machines. Each has its own complexity and use case. Extrusion blow molding machines are simpler and cheaper. Injection machines need precision, making them more expensive. Stretch blow machines combine processes, which affects their price.

Bigger machines produce more parts per hour. They require stronger components and advanced technology, increasing the cost. Smaller machines are suitable for startups or small-scale production.

Well-known brands charge more for reliability and durability. Lesser-known brands may offer cheaper options but could need frequent maintenance.

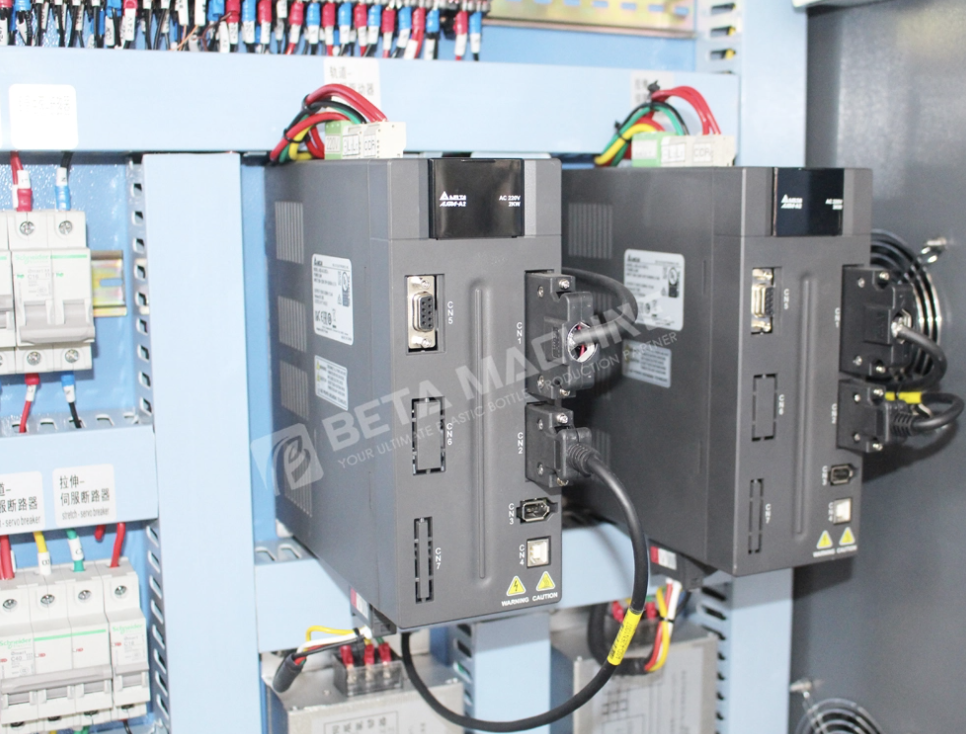

Automation, advanced controls, or specialized molds raise the price. But they can improve productivity and reduce labor costs over time.

The quality of steel or aluminum used impacts cost. Higher-grade materials increase machine lifespan but raise the upfront investment.

To understand the total cost, businesses must look beyond the sticker price. Here’s a general breakdown:

| Cost Component | Typical Range (USD) | Notes |

|---|---|---|

| Initial Purchase Price | $50,000 – $500,000+ | Depends on size, type, and cavity count |

| Installation & Setup | $10,000 – $50,000 | Site prep, transport, professional setup |

| Annual Maintenance | $5,000 – $20,000 | Prevents breakdowns and prolongs lifespan |

| Operating Costs | Varies by labor, energy, raw materials | Production scale dependent |

| Depreciation & Resale | N/A | High-quality brands retain value longer |

Small-scale machines: usually under $100,000.

High-capacity machines: can exceed $500,000.

Maintenance keeps machines running efficiently and prevents downtime.

Forms hollow parts using a molten tube called parison.

Common for bottles, containers, and simple hollow items.

Cost range: $3,000 for single-cavity molds, up to $25,000 for multi-cavity molds.

Variants:

Continuous EBM feeds parison constantly.

Intermittent EBM produces individual parts and is usually less expensive.

Combines injection molding and blowing.

Produces precise, high-quality bottles and tubes.

Cost range: $4,700 – $40,000; can go up to $89,500 for multi-cavity machines.

Ideal for pharmaceutical and cosmetic containers.

Starts with injection pre-form, then stretches and blows it.

Common for PET bottles like soda or water.

Cost range: $25,000 – $45,000.

Higher price includes better output and reduced labor costs.

Blow molding and injection molding serve different purposes, which is reflected in their costs.

| Feature | Blow Molding | Injection Molding |

|---|---|---|

| Product Type | Hollow parts (bottles, tanks) | Solid parts (caps, combs, housings) |

| Machine Cost | Lower | Higher |

| Mold Cost | $3,000 – $25,000 | $3,000 – $90,000+ |

| Production Speed | Moderate | Fast for high-volume |

| Material Flexibility | Soft and flexible plastics | Hard plastics, thermosets |

| Design Complexity | Moderate | High precision required |

Blow molding: better for hollow, low-cost production.

Injection molding: ideal for solid, detailed, high-volume parts.

Before making a purchase, it’s crucial to determine the primary purpose of the blow molding machine. If your goal is to produce hollow parts such as bottles, containers, or automotive fuel tanks, blow molding is the ideal choice. This process is specifically designed to create lightweight, hollow components efficiently. However, if your production requirements include solid parts, injection molding would be a more suitable option. Understanding the specific needs of your production will help you select the right type of machine for your application.

Your budget plays a significant role in the decision-making process. For startups or small businesses, selecting smaller, more affordable machines can be a practical approach. These machines are often sufficient for initial production needs and allow for a lower initial investment. On the other hand, larger companies with higher production demands often invest in high-tech, high-capacity machines. These machines offer advanced features and higher efficiency, which can lead to long-term cost savings and increased productivity. However, they come with a higher upfront cost. Balancing your budget with your production needs is essential to make a cost-effective decision.

The volume of production is another critical factor to consider. Higher-capacity machines can significantly reduce production time and increase efficiency, especially for large-scale operations. However, these machines come with a higher upfront cost and may require more space. If your production volume is relatively low, a smaller machine may be more appropriate and cost-effective. Assessing your current and projected production volumes will help you choose a machine that meets your needs without over-investing in capacity.

Maintenance requirements can vary widely between different brands and models of blow molding machines. Some brands may offer cheaper machines, but these often come with the trade-off of requiring more frequent maintenance. This can lead to increased downtime and higher maintenance costs over time. On the other hand, more expensive machines from reputable brands may offer better build quality and reliability, reducing the frequency of maintenance and repairs. Consider the long-term maintenance costs and the reliability of the machine when making your decision.

When it comes to managing the costs associated with blow molding machines, careful planning and strategic decision-making can lead to significant savings without compromising on quality or efficiency. Here are some practical tips to help you manage these costs effectively:

Choosing the appropriate size of the blow molding machine is crucial. While it might be tempting to opt for a larger machine, bigger isn’t always better. A machine that is too large for your production needs can lead to unnecessary expenses in terms of energy consumption, maintenance, and initial purchase cost. Conversely, a machine that is too small may not meet your production demands, leading to inefficiencies and potential bottlenecks. Therefore, it’s important to accurately assess your current and future production needs to select a machine that fits perfectly.

Before making a purchase, it’s essential to compare multiple brands and suppliers. Different manufacturers offer varying levels of quality, features, and prices. By conducting thorough research and comparing options, you can find the best value for your money. Look for suppliers with a good reputation for reliability, customer service, and after-sales support. Reading reviews and seeking recommendations from industry peers can also provide valuable insights.

Not all features offered by blow molding machines are necessary for every application. It’s important to evaluate which features are essential for your specific production needs and which ones can be omitted to save costs. Advanced features such as automated controls, high-speed capabilities, and advanced monitoring systems can significantly increase the price of the machine. While these features can be beneficial, they may not be necessary if your production requirements are relatively simple. Focus on the features that will directly contribute to your production efficiency and quality.

Regular maintenance is a critical aspect of managing blow molding machine costs. Preventive maintenance can help identify potential issues before they lead to costly breakdowns. By scheduling regular maintenance checks, you can ensure that your machine operates efficiently and prolong its lifespan. This not only reduces the risk of unexpected repairs but also helps in maintaining consistent production quality. Keep a maintenance schedule and follow the manufacturer’s recommendations for routine checks and servicing.

For cost savings, consider purchasing refurbished machines from reputable suppliers. Refurbished machines are often available at a fraction of the cost of new ones and can offer significant savings without sacrificing performance. Ensure that the refurbished machine comes with a warranty and has been thoroughly inspected and tested by the supplier. This can be a cost-effective solution, especially for small to medium-sized businesses looking to reduce their initial investment.

Around $50,000 for small, single-cavity machines.

EBM is cheapest, IBM is mid-range, SBM is higher-end.

Maintenance, labor, energy, and raw materials.

Yes. Efficient machines increase output, offsetting initial investment.

Investing in a blow molding machine is a critical decision for any manufacturing business. Understanding the cost of blow molding machines, from initial purchase to ongoing maintenance, helps you plan effectively and avoid unexpected expenses. By considering factors like machine type, size, brand, production volume, and necessary features, you can select a machine that balances quality, efficiency, and affordability.

At BETA Plastic Machinery, we specialize in providing high-quality blow molding machines tailored to your production needs. Our team offers expert guidance on machine selection, customization, and after-sales support to ensure you get the best return on your investment. Whether you’re looking for extrusion, injection, or stretch blow molding machines, BETA can help you achieve higher productivity while keeping costs manageable.