Language

Views: 0 Author: Site Editor Publish Time: 2025-09-16 Origin: Site

Blow molding is one of the most important techniques in modern plastic manufacturing. From the soda bottle in your fridge to the detergent container in your laundry room, many everyday products come to life through this process. But not all blow molding is the same. Two of the most widely used methods—extrusion blow molding (EBM) and stretch blow molding (SBM)—differ in how they shape plastics, the materials they use, and the kinds of products they create.

In this guide, we’ll explore extrusion blow molding and stretch blow molding in detail, comparing their processes, advantages, limitations, and typical applications. By the end, you’ll have a clear idea of which method fits your production needs best.

Blow molding is a way to make hollow plastic products. It works by heating plastic until it’s soft, then forcing air inside. The air pushes the material outward against a mold, creating a hollow shape. Once cooled, it holds the final form.

People see blow molded products everywhere: water bottles, shampoo containers, fuel tanks, and even toys. Companies choose blow molding because it’s fast, cost-effective, and ideal for lightweight packaging.

Extrusion blow molding starts by melting plastic into a tube called a parison. The tube drops between two halves of a mold. The mold closes tight, then air gets blown inside. The parison inflates like a balloon until it touches the mold walls. Finally, the product cools and is ejected.

Uses materials like HDPE, PP, PVC.

Works for bottles, jugs, and industrial containers.

Allows handles, complex curves, and thick walls.

Lower mold costs compared to other processes.

Flexible shapes and designs possible.

Good for medium to large containers.

Hard to control wall thickness evenly.

Not ideal when you need crystal-clear bottles.

Stretch blow molding is slightly different. Instead of starting with a tube, it begins with a small solid piece called a preform. The preform is heated, stretched lengthwise by a rod, and blown outward into a mold. The stretching step gives the plastic extra strength.

There are two main types:

One-step SBM – preform made, stretched, and blown in the same machine.

Two-step SBM – preform injection molded first, stored, then later reheated and blown.

Primarily uses PET resin.

Creates lightweight, clear, strong bottles.

Ideal for beverages and cosmetics.

Produces bottles with high transparency.

Strong, thin walls that resist pressure.

Perfect for carbonated and bottled water.

Higher mold and equipment cost.

Limited mainly to PET and some PP.

Extrusion blow molding (EBM) and stretch blow molding (SBM) are two distinct processes used in plastic manufacturing, each with its own unique characteristics and applications. In EBM, a plastic tube, known as a parison, is extruded and then inflated inside a mold. This process allows for the creation of a wide variety of shapes and sizes, making it highly versatile for different types of products. On the other hand, SBM involves stretching a preform lengthwise before it is blown inside a mold. This stretching process helps to achieve uniform wall thickness and high clarity, which are essential for certain types of containers.

The choice of materials also differs between the two processes. EBM commonly uses high-density polyethylene (HDPE), polypropylene (PP), and polyvinyl chloride (PVC). These materials are known for their durability and versatility, making them suitable for a wide range of applications. In contrast, SBM primarily uses polyethylene terephthalate (PET). PET is renowned for its clarity, strength, and lightweight properties, making it ideal for applications where these characteristics are crucial.

The characteristics of the final products produced by EBM and SBM also vary significantly. EBM is well-suited for creating products with handles, thick walls, and large opaque items. This makes it ideal for applications such as detergent bottles, oil containers, and automotive tanks, where durability and functionality are paramount. SBM, on the other hand, excels in producing lightweight, clear, and high-strength bottles. This makes it the preferred choice for soda bottles, water bottles, and cosmetics containers, where appearance and strength are critical.

Cost considerations play a significant role in choosing between EBM and SBM. EBM generally has lower mold costs and is more flexible for shorter production runs. This makes it a cost-effective option for manufacturers who need to produce a variety of products in smaller quantities. SBM, however, has a higher startup cost due to the more complex machinery and molds required. Despite this, it is highly efficient for large-scale production of PET bottles, making it a more economical choice for high-volume runs.

The typical applications for EBM and SBM further highlight their differences. EBM is commonly used for manufacturing detergent bottles, oil containers, and automotive fuel tanks. These products benefit from the robustness and versatility that EBM provides. SBM, in contrast, is widely used for producing soda bottles, water bottles, and cosmetics containers. The high clarity and strength of PET bottles produced through SBM make them ideal for these applications, where both functionality and aesthetics are important.

| Feature | Extrusion Blow Molding (EBM) | Stretch Blow Molding (SBM) |

|---|---|---|

| Process | Molten parison inflated in mold | Heated preform stretched + blown |

| Materials | HDPE, PP, PVC | PET mainly |

| Product Clarity | Opaque or translucent | Crystal-clear, glossy |

| Product Types | Jugs, drums, fuel tanks | Water, soda, cosmetic bottles |

| Mold Cost | Lower | Higher |

| Strength | Moderate | Very high due to stretching |

| Applications | Household, industrial, automotive | Beverages, cosmetics, personal care |

The choice between extrusion blow molding (EBM) and stretch blow molding (SBM) depends largely on your specific production needs and goals. If you are manufacturing large, opaque containers such as detergent bottles or automotive fuel tanks, extrusion blow molding is likely the better option. This process is well-suited for creating robust, functional containers that do not require high clarity. On the other hand, if your goal is to produce clear, lightweight bottles for beverages or cosmetics, stretch blow molding is the superior choice. SBM excels in creating high-strength, transparent containers that are both visually appealing and efficient for packaging liquids.

When deciding between these two processes, several factors should be carefully considered:

Consider the nature of the product you are packaging. For industrial applications such as chemical containers or large storage tanks, EBM is typically more appropriate due to its ability to handle thicker walls and more substantial sizes. In contrast, for beverage packaging or cosmetics, where clarity and lightweight design are crucial, SBM is the preferred method. The product type will significantly influence the choice of molding process.

The material you plan to use is another critical factor. EBM commonly utilizes high-density polyethylene (HDPE), polypropylene (PP), and polyvinyl chloride (PVC). These materials are known for their durability and versatility, making them suitable for a wide range of applications. SBM, however, primarily uses polyethylene terephthalate (PET). PET is renowned for its clarity, strength, and lightweight properties, making it ideal for applications where these characteristics are essential. The material choice will not only affect the production process but also the final product’s performance and appearance.

The production volume is a significant consideration. EBM is more flexible and cost-effective for small to medium production runs. It allows for greater versatility in product design and can accommodate a variety of shapes and sizes without the need for extensive setup costs. SBM, on the other hand, is highly efficient for mass production, particularly for PET bottles. The higher startup costs associated with SBM are offset by its efficiency and speed in large-scale production runs. Therefore, the volume of production will play a crucial role in determining the most cost-effective and efficient molding process.

Finally, your budget will heavily influence the choice of molding process. EBM generally has lower mold costs and is more suitable for shorter production runs. This makes it a cost-effective option for manufacturers who need to produce a variety of products in smaller quantities. SBM, however, has a higher startup cost due to the more complex machinery and molds required. Despite this, it is highly efficient for large-scale production of PET bottles, making it a more economical choice for high-volume runs. Balancing the initial investment with long-term efficiency and cost savings is essential in making the right decision.

EBM is common in household chemicals, automotive tanks, and industrial packaging.

SBM makes PET bottles for water, soda, juices, and cosmetic packaging.

Yes, upfront costs are lower for molds, but unit cost may be higher at scale.

PET can stretch without breaking, giving bottles clarity and strength.

It can, but they won’t be as clear or strong as SBM bottles.

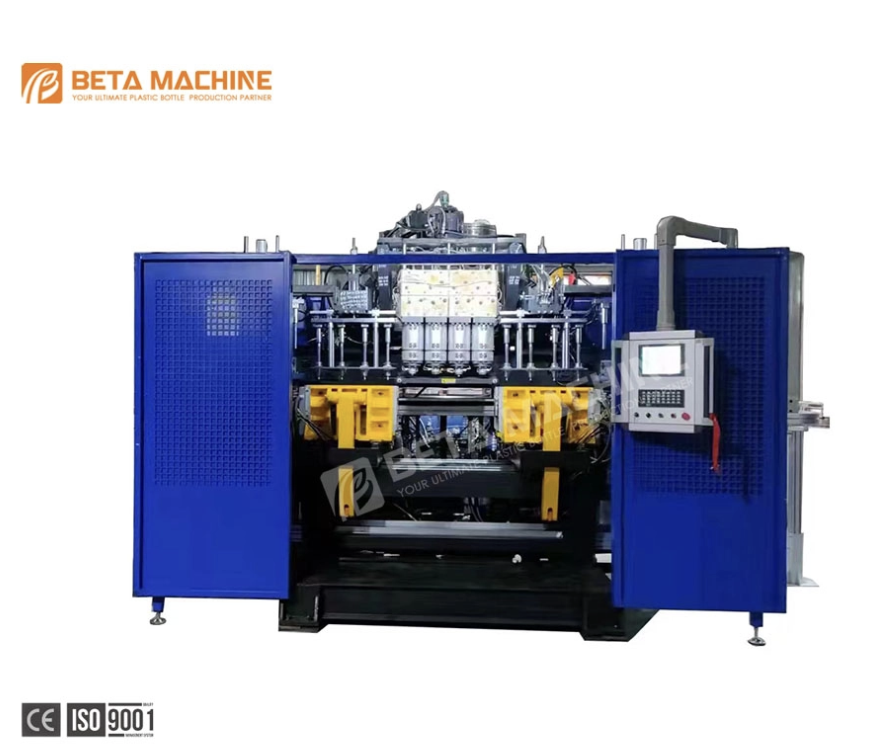

Both extrusion blow molding (EBM) and stretch blow molding (SBM) play vital roles in the plastic manufacturing world. If your business is looking for efficient, high-quality blow molding machinery, BETA is here to help. With advanced technology, reliable equipment, and strong industry expertise, BETA provides solutions tailored to your production needs. Whether you’re scaling up beverage packaging or diversifying industrial containers, we can help you achieve consistency, efficiency, and cost savings.