The SSLQD Series Small Bottle High Speed Linear Blowing Machine is a fully automatic PET bottle blowing solution designed for 0.2–2L containers. With flexible cavity configurations from 4 to 10, high-speed output, and energy-saving operation, it is ideal for beverage and packaging manufacturers seeking efficient and reliable production.

Currently the most popular blow molding machine equipment, suitable for various production capacity needs.

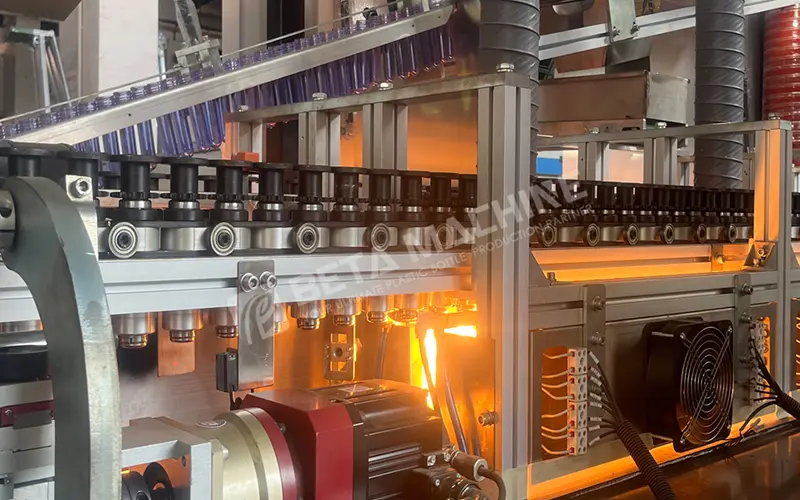

The continuous rotating preform feeding system is tightly combined with the

machine platform, which effectively reduces the area occupied by the

machine platform. The preform has no overturn and with simple structure.Continuous heating system, the heating pitch between each preform is 38 mm,

which can effectively use the lamp tube heating space,highly improved the heating efficiency.Servo motor is used to ensure high-speed operation and precise positioning. This machine is suitable for drinking water, carbonated beverage, fruit juice, tea and milk product.,etc in PET bottles with production capacity ranges from 4,000BPH to 20,000BPH based on 500ml water bottle.

![]()

Supports 4–10 cavities with output up to 20,000 BPH (500ml).

![]()

Human-machine interface enables simple operation and easy monitoring.

![]()

Rotating feeding design reduces footprint and ensures stable preform transfer.

![]()

Servo motors ensure high-speed operation and accurate positioning.

PET pure water bottles

Mineral water bottles

Carbonated beverage bottles

Sparkling beverage bottles

Juice, tea, and milk bottles

Cosmetic bottles

Wide-mouth and heat-resistant PET bottles

Stable, efficient, and intelligent bottle production workflow

Fully automatic preform sorting and loading system ensures fast, accurate

feeding, reduces labor costs, and improves overall production stability.

Automatic detection and separation system ensures accurate positioning

of preforms before heating and blowing.

Infrared lamp heating with adjustable zones ensures uniform preform

temperature, lower energy consumption, and high bottle transparency.

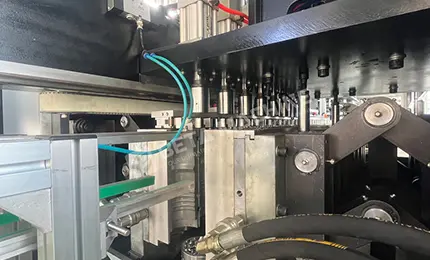

Servo-driven mold clamping ensures precise synchronization, strong locking

force, reduced mold lines, and quick mold change.

Servo-controlled stretching provides precise stroke adjustment, flexible

operation, and consistent bottle forming.

Efficient cooling system protects bottle necks, speeds up mold cooling,

and improves overall production efficiency.

What bottle size range does this machine support?

The SSLQD small bottle series supports PET bottles from 0.2L to 2L.

How many cavities are available?

The machine can be configured from 4 cavities up to 10 cavities.

What is the maximum production capacity?

Up to 20,000 bottles per hour based on 500ml bottles.

Is it suitable for continuous production?

Yes, it features a fully automatic production process with PLC control.

Are branded components used in the machine?

Yes, the machine uses well-known components such as Delta PLC, AIRTAC cylinders, and SMC silencers.

| Model No. | SSLD-4 | SSLQD-6-0.6L | SSLQD-6D-1.5L | SSLQD-6-2.5L | SSLQD-8-0.6L | SSLQD-8D-1.5L | SSLQD-10-0.6L |

| Production Capacity(BPH) |

4000-6000 | 9000-12000 | 8000-11000 | 6000 | 12000-16000 | 10000-15000 | 16000-20000 |

| Container Volume(L) |

0.2-1.5 | 0.2-0.6 | 0.2-1.5 | 1-2.25 | 0.2-0.6 | 0.2-1.5 | 0.2-0.6 |

| Bottle Height(mm) | 120-330 | 45-65 | 120-330 | 120-330 | 120-230 | 120-330 | 120-230 |

| bottle diameter(mm) | 45-105 | 50-130 | 45-105 | 45-120 | 45-65 | 45-105 | 45-65 |

| Host dimensions(m) | 4*1.5*2.67 | 5.4*1.6*2.67 | 5.9*1.6*2.67 | 6.36*1.6*2.67 | 5.9*1.6*2.67 | 6.9*1.6*2.67 | 7.2*1.6*2.67 |

| Preform unscrambler dimensions(m) |

2*2*2.5 | 2*2*2.5 | 2*2*2.5 | 2*2*2.5 | 2*2*2.5 | 2*2*2.5 | 2*2*2.5 |

| Working pressure(Mpa) | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Installation power(kw) | 55 | 90 | 95 | 127 | 127 | 127 | 159 |

| Mold cooling(HP) | 5 | 8 | 10 | 10 | 10 | 12 | 12 |

| Weight(T) | 3.5 | 5.5 | 6 | 6 | 6 | 6.5 | 7 |