Cap compression molding machine is for making caps from plastic materials extruded from extruder cutted by segregation plate through screw driving and shared to each cavity equably.

Hydraulic Plastic Cap Compression Molding Machine(High Speed Type)

· The machine adopts the High-Medium-Low hydraulic pump system, compare with the old type that only have High Hydraulic pump system,it reduces the oil pump motor load and save 50% of power consumption.

Applied Range

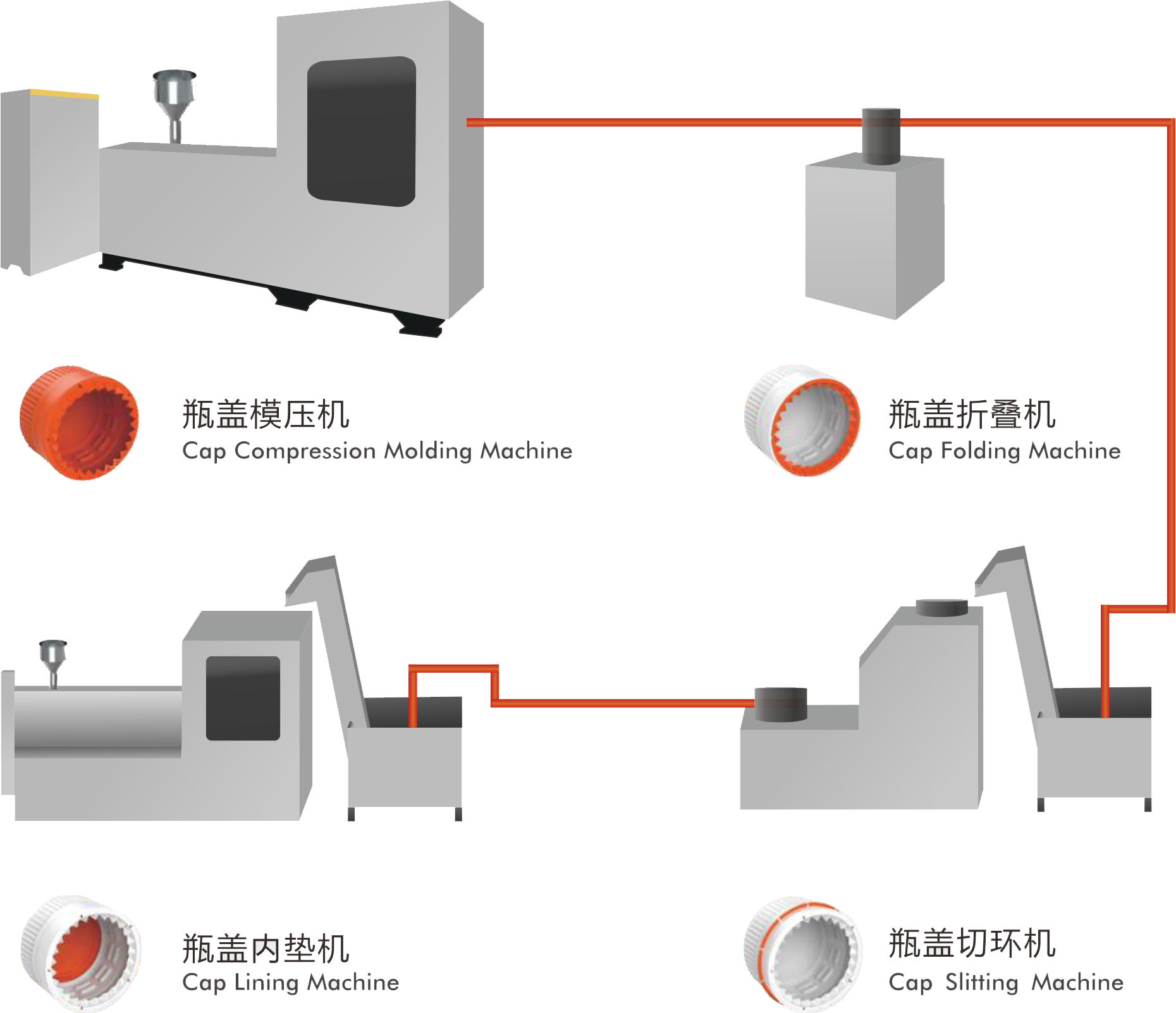

Cap Manufacturing Process

Cap compression machine is for making caps from plastic materials extruded from extruder cutted by segregation plate through screw driving and shared to each cavity equably.

Machine Unique Advantage

The main cap mould material use proprietary material,it has excellent wear resistance, corriosion resistance and polishing of optical activity, good machinability, and quench stability.

Braces with high hardness, high wear resistance of alloy steel, not easy to burn.

Coating Advantage

· Cap mould specified coating by Swiss company

· The coating thickness of thin steel, and strong bonding force

· High hardness

· Lower friction and wear reducing

· Can effectively extend the use life of the molds 2-6 times

Automatic High Speed Type Plastic Cap Compression Molding Cap Making Machine

| Type | SY-30BY-H-24T | SY-30BY-H-36T | SY-30BY-H-48T |

| Raw Materials | PP/HDPE/LDPE | PP/HDPE/LDPE | PP/HDPE/LDPE |

| Capacity(pcs/hr) | 32000-34000 | 48000-54000 | 66000-70000 |

| Diameter | 22-42mm | 22-42mm | 22-42mm |

| Height | 10-25mm | 10-25mm | 10-25mm |

| Mold Number | 24 cavity | 36 cavity | 48 cavity |

| Actual Power Consumption | 28-30KW | 48-52KW | 63-67KW |

| Air Compressor | 0.8 mpa; 1.5m³ | 1.0 mpa; 3.0m³ | 1.0 mpa; 3.0m³ |

| Voltage | 220v/380v 50-60hz | 220v/380v 50-60hz | 220v/380v 50-60hz |

| Weight | 5500kg | 7800kg | 8500kg |

| Dimensions(L*W*H) | 4500*1800*2100mm | 6000*2100*2200mm | 7000*2100*2200mm |