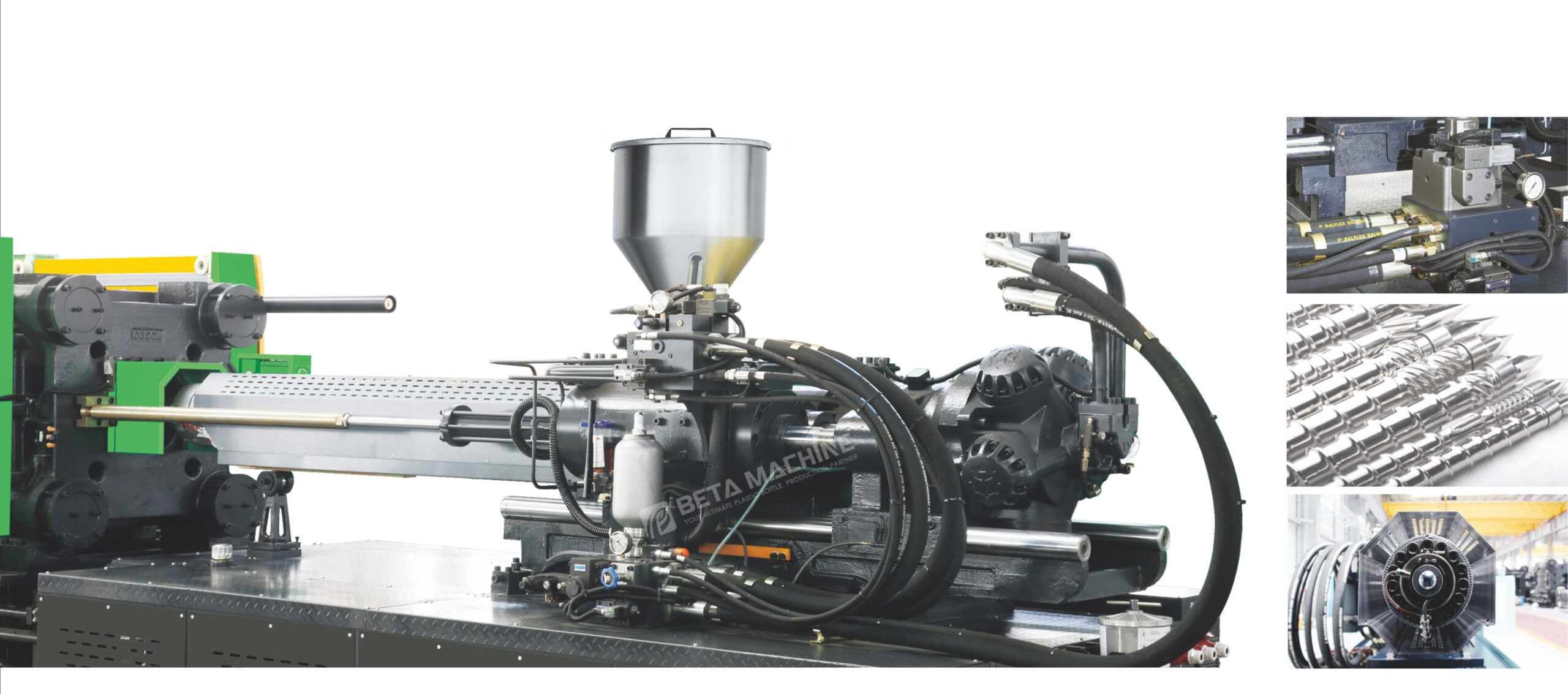

1* Increase the injection volume, which is more suitable for the production of multi-cavity products. Tailored according to different requirements, it is more advantageous for the production of packaging, deep cavity and high speed PET preform products

2*PET special screw significantly increases the melting speed and injection volume, reduces the plasticizing temperature, effectively improve the shrinkage of the preform and improve the transparency

3*Increase the thimble force and ejection stroke, which is more suitable for deep cavity PET preform molding

Automatic PET Prefrom Injection Molding Machine

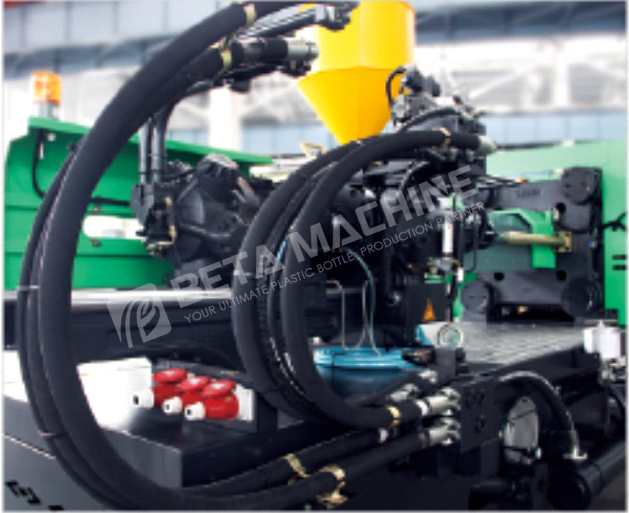

1.High response oil-way system.

Modularized energy conservation high response oil-way system could improve the speed of the complete machine and also saves energy consumption.

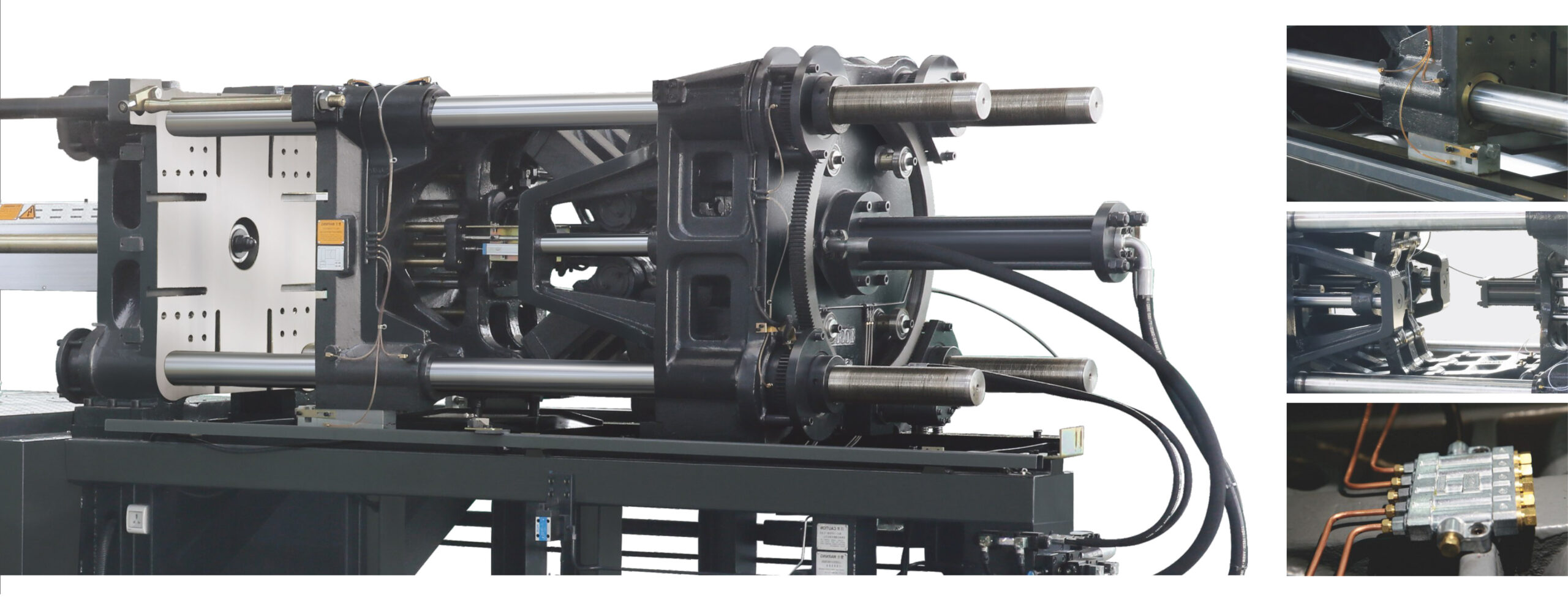

2.Clamping unit

The two-plate clamping unit is a compact, space-saving design. In addition, the perfect frictionless design of the two plates ensures the best template parallelism and the most sensitive mold protection through linear guides. This ensures maximum customer safety and product quality.

3.Injection Unit

1-Optimize injection unit

Technical parameters

| Model | Unit | YJPT200 | YJPT230 | YJPT260 |

| Injection Device | 62 | 62 | 72 | |

| Screw Diameter | mm | 24:1 | 24:1 | 24:1 |

| Screw Diameter Ratio | L/D | 814 | 814 | 1300 |

| Theoretical Shot Volume | cm3 | 830 | 830 | 1320 |

| Injection Stroke | g | 270 | 270 | 320 |

| Injection Pressure | Mpa | 131 | 131 | 137 |

| Clamping Unit | ||||

| Clamping Force | KN | 2000 | 2300 | 2600 |

| Togglestroke | mm | 436 | 500 | 560 |

| Space Between Tie-bars | mm*mm | 460*460 | 520*520 | 580*580 |

| Minn-max Mould Thicness | mm | 180-500 | 220-550 | 250-610 |

| Ejection Stroke | mm | 140 | 170 | 170 |

| Ejection Force | KN | 70 | 102 | 102 |

| Other | ||||

| Maximum System Pressure | Mpa | 16 | 16 | 16 |

| Oil Pump System Power(conventional) | KW | 22 | 31.4(Servo) | 48.2(Servo) |

| Heater Power | KW | 22.4 | 22.4 | 35.7 |

| Overall Diameter | m | 6.04*1.46*2.04 | 6.36*1.5*2.16 | 7.18*1.64*2.26 |

| Machine Weight(About) | t | 6 | 7.5 | 8.6 |

| Model | Unit | YJPT360组合式 | YJPT400组合式 | ||

| A2000 | A3000 | A2000 | A3100 | ||

| Injection Device | 82 | 95 | 82 | 95 | |

| Screw Diameter | mm | 24:1 | 24:1 | 24:1 | 24:1 |

| Screw Diameter Ratio | L/D | 2000 | 3100 | 2000 | 3100 |

| Theoretical Shot Volume | cm3 | 2050 | 3160 | 2050 | 3160 |

| Injection Stroke | g | 390 | 440 | 390 | 440 |

| Injection Pressure | Mpa | 132 | 133 | 132 | 133 |

| Clamping Unit | |||||

| Clamping Force | KN | 3600 | 4000 | ||

| Togglestroke | mm | 660 | 730 | ||

| Space Between Tie-bars | mm*mm | 680*680 | 720*720 | ||

| Minn-max Mould Thicness | mm | 280-680 | 280-830 | ||

| Ejection Stroke | mm | 190 | 230 | ||

| Ejection Force | KN | 180 | 180 | ||

| Other | |||||

| Maximum System Pressure | Mpa | 16 | 16 | 16 | 16 |

| Oil Pump System Power(conventional) | KW | 55.5(Servo) | 79.6 (Servo) | 55.5(Servo) | 79.6 (Servo) |

| Heater Power | KW | 49.5 | 60.3 | 49.5 | 60.3 |

| Overall Diameter | m | 8.2*1.86*2.36 | 8.5*1.86*2.36 | 8.9*1.95*2.5 | 9.2*1.95*2.5 |

| Machine Weight(About) | t | 14 | 15.5 | 15 | 16.5 |