Cap compression molding machine is for making caps from plastic materials extruded from extruder cutted by segregation plate through screw driving and shared to each cavity equably.

Hydraulic Plastic Cap Compression Molding Machine(Standard Type)

· This machine adopts the oil pump to provide the pressure,the pressure is bigger and stable,and it can provide the same pressure to every mold.So the cap made from this machine looks more beautiful and with tight structure.Also it is good for improving the mold use life.

· Cap molding speed faster,less difference of required quality.Moreover,this type machine expands the product type and range of cap diameter to satisfy the individuating demands of customer.

· From the consideration of energy and material consumptions and environmental protection,this compression molding machine is the trend of present and future.It provides a good platform for intelligent,informational and control process.

· This machine has the following advantages:high degree of automation,high efficiency,change of different molds,multiuse of one machine and so on.

Applied Range

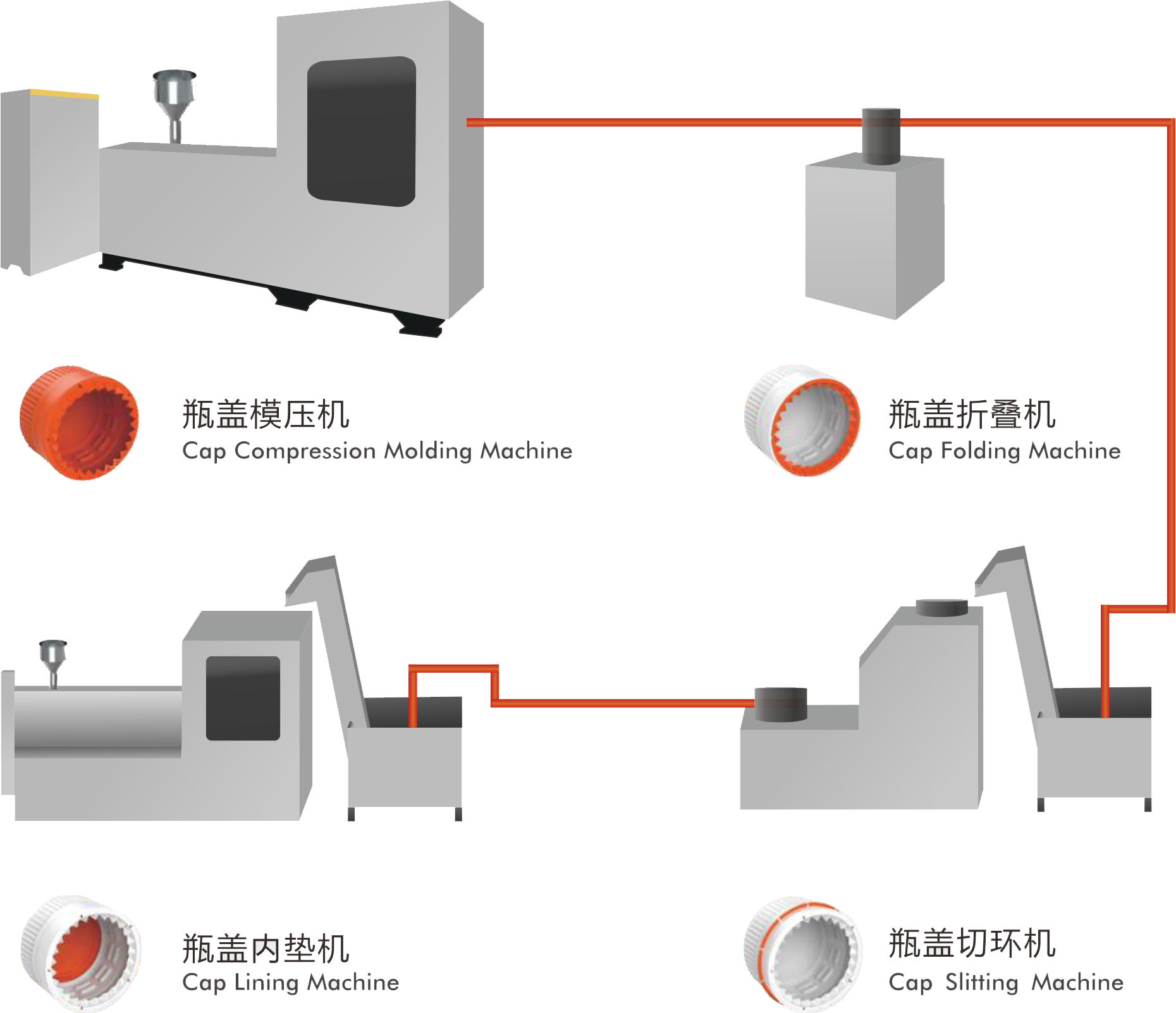

Cap Manufacturing Process

Cap compression machine is for making caps from plastic materials extruded from extruder cutted by segregation plate through screw driving and shared to each cavity equably.

Machine Unique Advantage

The main cap mould material use proprietary material,it has excellent wear resistance, corriosion resistance and polishing of optical activity, good machinability, and quench stability.

Braces with high hardness, high wear resistance of alloy steel, not easy to burn.

Coating Advantage

· Cap mould specified coating by Swiss company

· The coating thickness of thin steel, and strong bonding force

· High hardness

· Lower friction and wear reducing

· Can effectively extend the use life of the molds 2-6 times

Automatic Plastic Cap Compression Molding Machine Chemical Cap Making Machine

| Type | SY-30A-30T | SY-30A-36T |

| Raw Materials | PP | PP |

| Capacity(pcs/hr) | 10000-12000 | 15000-18000 |

| Diameter | 13-34mm | 13-22mm |

| Height | 4-7mm | 4-7mm |

| Mold Number | 30 cavity | 36 cavity |

| Actual Power Consumption | 6-8KW | 6-8KW |

| Air Compressor | 0.6 mpa; 0.5m³ | 0.6 mpa; 0.5m³ |

| Voltage | 220v/380v 50-60hz | 220v/380v 50-60hz |

| Weight | 2800kg | 3100kg |

| Dimensions(L*W*H) | 2400*1300*1700mm | 2400*1300*1700mm |