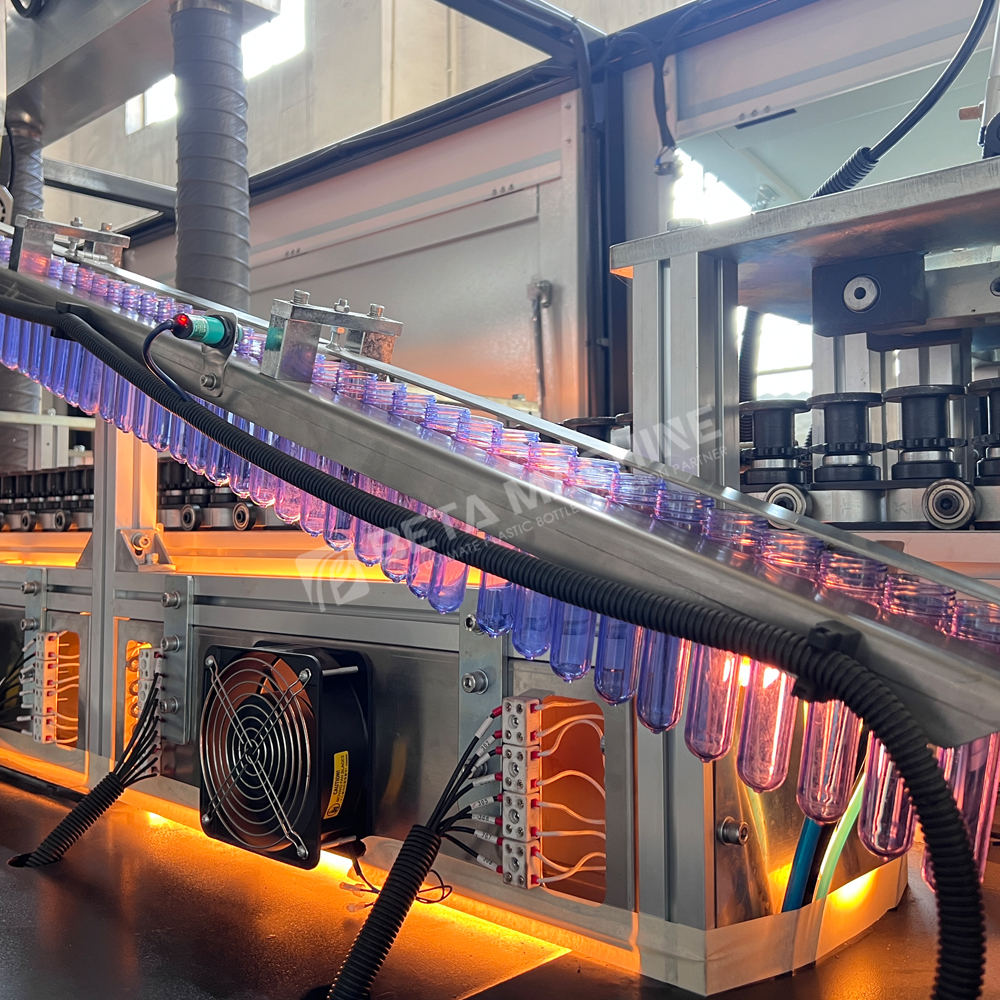

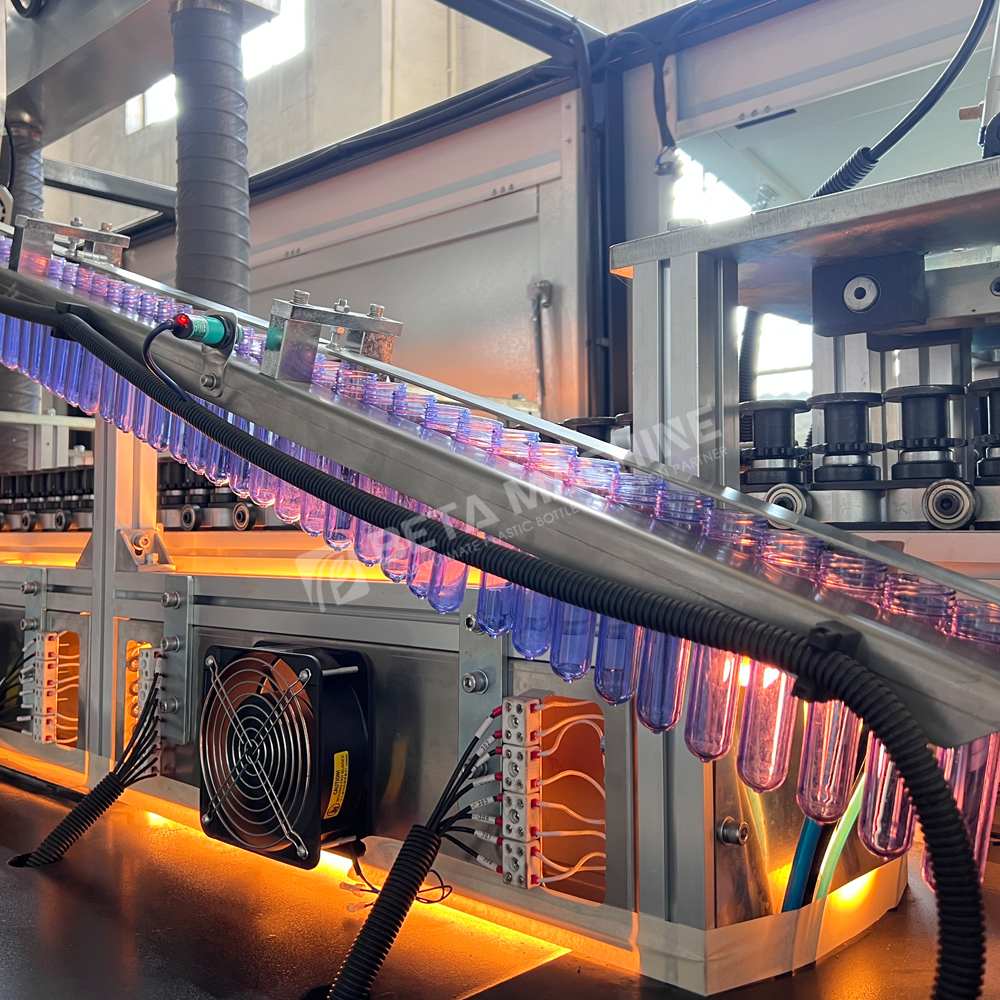

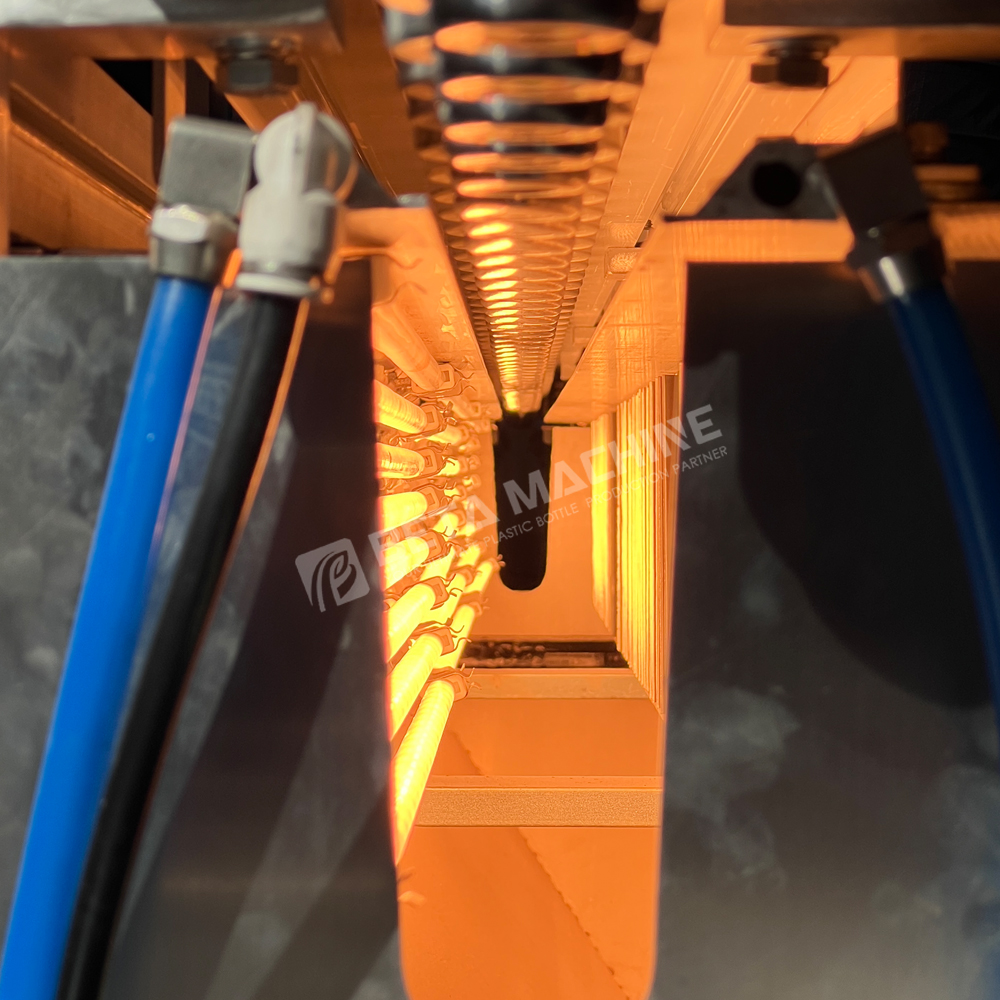

The BETA high speed & energy saving series is a reliable two-step blow-down stretch automatic blowing machine that offers stability. It is compatible with 4 to 10 cavity molds and is suitable for producing a variety of bottles including carbonated beverages, sparkling beverages, pure water, mineral water, fruit juice, cosmetics, large diameter, high temperature resistant, and other packaging bottles.

BETA high speed &energy saving series is a stable two-step blow-down stretch automatic blowing machine.It can be used from 4 cavity to 10 cavity,suitable for blowing any kind of carbonated beverage bottle,sparkling beverage bottle,pure water bottle, mineral water bottle,fruit juice beverage bottle,cosmetic bottles,large diameter bottles, high temperature resistance bottles and other packaging bottles.

Welcome to China Molding Machine Supplier, a leading provider of advanced plastic processing machinery. Our High-Speed Automatic Plastic Bottle Blowing Machine with 4 Cavities is designed to deliver exceptional efficiency and reliability for the production of PET bottles used in beverages, food packaging, and other consumer goods.

| Parameter | Details |

|---|---|

| Number of Cavities | 4 |

| Max. Bottle Capacity | 2,000 ml |

| Neck Size | 18-38 mm |

| Max. Bottle Diameter | 105 mm |

| Max. Bottle Height | 330 mm |

| Injection Capacity | 238 cm³ |

| Injection Pressure | 174 Mpa |

| Clamping Force | 80 KN |

| Power Supply | 380V, 50Hz/3PH |

| Rated Power | 49 kW |

| Air System | HP Air Compressor: 3.0 m³/min, 3.0 Mpa<br>LP Air Compressor: 1.6 m³/min, 1.0 Mpa |

| Cooling Water | Water Chiller: 3 HP |

| Machine Dimensions (L×W×H mm) | 4,200×2,100×2,400 |

| Weight | 5,000 kg |

|

Model No.

|

NBH-4

|

NBQH-6

|

NBQH-6D

|

NBQH-8

|

NBQH-8D

|

NBQH-10

|

|

Production Capacity(BPH)

|

4000-6000

|

9000-12000

|

8000-11000

|

12000-16000

|

10000-15000

|

16000-20000

|

|

Container volume(L)

|

0.3-1.5

|

0.3-0.6

|

0.3-1.5

|

0.3-0.6

|

0.3-1.5

|

0.3-0.6

|

|

Bottle height(mm)

|

120-330

|

45-65

|

120-330

|

120-230

|

120-330

|

120-230

|

|

Bottle diameter(mm)

|

45-105

|

50-130

|

45-105

|

45-65

|

45-105

|

45-65

|

|

Preform length(mm)

|

50-130

|

50-130

|

50-130

|

50-130

|

50-130

|

50-130

|

|

Host dimensions(m)

|

4*1.5*2.67

|

5.4*1.6*2.67

|

5.9*1.6*2.67

|

5.9*1.6*2.67

|

6.9*1.6*2.67

|

7.2*1.6*2.67

|

|

Bottle unscrambler dimensions(m)

|

2*2*2.5

|

2*2*2.5

|

2*2*2.5

|

2*2*2.5

|

2*2*2.5

|

2*2*2.5

|

|

High pressure air pressure(Mpa)

|

4

|

4

|

4

|

4

|

4

|

4

|

|

Working pressure(Mpa)

|

0.8

|

0.8

|

0.8

|

0.8

|

0.8

|

0.8

|

|

Voltage(V)

|

380

|

380

|

380

|

380

|

380

|

380

|

|

Installation power(kw)

|

55

|

90

|

95

|

127

|

127

|

159

|

|

Actual power(%)

|

30-60

|

30-60

|

30-60

|

30-60

|

30-60

|

30-60

|

|

Mold cooling(HP)

|

5

|

8

|

10

|

10

|

12

|

12

|

|

Applicable material

|

PET

|

PET

|

PET

|

PET

|

PET

|

PET

|

|

Weight(T)

|

3.5

|

5.5

|

6

|

6

|

6.5

|

7

|