The SSLQD series automatic blow molding machines are high-performance PET bottle production solutions designed for 3–18.5L containers. Featuring reliable branded components, full automation, and energy-saving operation, they provide stable output and consistent bottle quality for large-volume packaging applications.

High-efficiency solution for small & medium batch production

The SSLQD series blow molding machines, including models SSLQD-1D, SSLQD-2D, SSLQD-2, SSLQD-3, and SSLQD-4, are engineered for efficient production of large PET bottles ranging from 3L to 18.5L. With production capacities from 600 to 3600 bottles per hour, they meet diverse output requirements across different packaging industries.

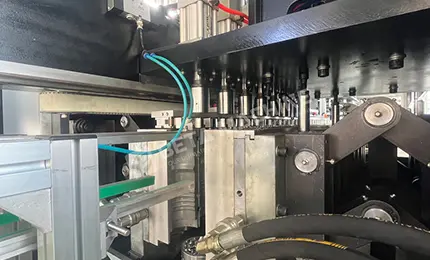

These machines adopt a fully automatic control system equipped with Delta PLC, a touch-screen interface, and servo-driven mechanisms, ensuring precise coordination and stable operation. High-quality components such as AIRTAC cylinders and SMC silencers enhance reliability and extend service life.

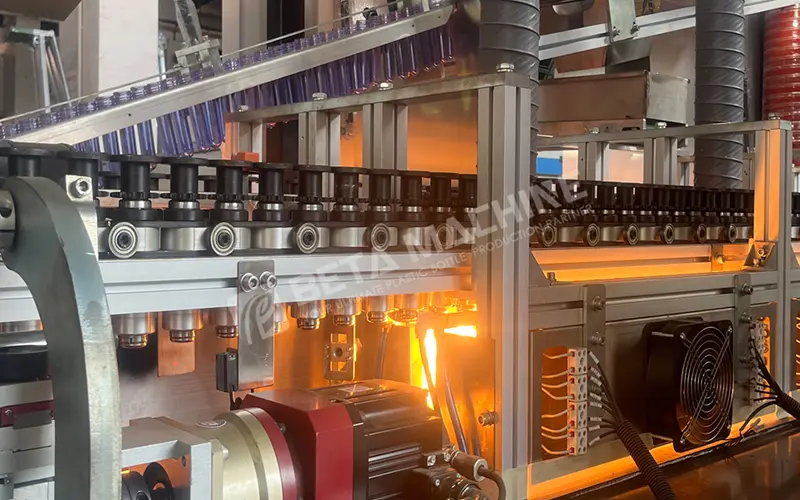

The infrared preheating system ensures uniform heating of PET preforms, resulting in precise bottle forming, consistent wall thickness, and excellent transparency. Combined with an energy-saving design and optimized mechanical structure, the SSLQD series reduces power consumption while maintaining high productivity. Easy operation, simple maintenance, and low downtime make it an ideal solution for long-term industrial production.

![]()

Supports PET bottles from 3L to 18.5L for diverse packaging needs.

![]()

Equipped with Delta PLC, servo systems, AIRTAC cylinders, and SMC silencers.

![]()

Ensures uniform wall thickness and stable bottle quality.

![]()

Automatic preform feeding, heating, blowing, and bottle discharge.

3–18.5L PET water bottles

Large edible oil containers

Household chemical bottles

Industrial liquid packaging containers

Custom large-volume PET bottles

Stable, efficient, and intelligent bottle production workflow

Fully automatic preform sorting and loading system ensures fast, accurate

feeding, reduces labor costs, and improves overall production stability.

Automatic detection and separation system ensures accurate positioning

of preforms before heating and blowing.

Infrared lamp heating with adjustable zones ensures uniform preform

temperature, lower energy consumption, and high bottle transparency.

Servo-driven mold clamping ensures precise synchronization, strong locking

force, reduced mold lines, and quick mold change.

Servo-controlled stretching provides precise stroke adjustment, flexible

operation, and consistent bottle forming.

Efficient cooling system protects bottle necks, speeds up mold cooling,

and improves overall production efficiency.

What bottle sizes can the SSLQD series produce?

The SSLQD series supports PET bottles ranging from 3L to 18.5L.

What is the production capacity of this series?

Depending on the model, output ranges from 600 to 3600 bottles per hour.

Is the SSLQD series fully automatic?

Yes, it operates fully automatically from preform feeding to bottle output.

Is it suitable for continuous production?

Yes, it features a fully automatic production process with PLC control.

Are branded components used in the machine?

Yes, the machine uses well-known components such as Delta PLC, AIRTAC cylinders, and SMC silencers.

| Model No. | Unit | SSLQD-1D | SSLQD-2D | SSLQD-2 | SSLQD-3 | SSLQD-4 |

| Container volume | L | 10-18.5 | 10-18.5 | 3-8 | 3-8 | 3-8 |

| Theoretical output | P/H | 600-800 | 1000-1500 | 1500-2000 | 2000-2800 | 3000-3600 |

| Bottle height | MM | 300-500 | 300-500 | 300-400 | 300-400 | 300-400 |

| Bottle diameter | MM | 200-280 | 200-280 | 150-200 | 150-200 | 150-200 |

| preform length | MM | 150-240 | 150-240 | 50-110 | 100-180 | 100-180 |

| Main machine size | MM | 3600*2100*2600 | 5400*2100*2600 | 4100*1900*2600 | 5100*1900*2600 | 6200*1900*2600 |

| Preform unscrambler size | MM | 2000*2000*2300 | 2000*2000*2300 | 2000*2000*2300 | 2000*2000*2300 | 2000*2000*2300 |

| High-Pressure Gas Pressure | 3.0MPA/8M³ | 3.0MPA/12M³ | 3.0MPA/6M³ | 3.0MPA/12M³ | 3.0MPA/12M³ | |

| Working Air Pressure | MPA | 0.8 | 0.8 | 0.8 | 0.8 | 0.8 |

| Operating Voltage | V | 380 | 380 | 380 | 380 | 380 |

| Total Installed Capacity 4PH 380V 50HZ |

KW | 60 | 105 | 100 | 120 | 140 |

| Operating Power | 30-60% | 30-60% | 30-60% | 30-60% | 30-60% | |

| Mold Cooling | HP | 5 | 8 | 5 | 8 | 10 |

| Applicable Materials | PET | PET | PET | PET | PET | |

| Machine Weight | T | 4.5 | 6 | 4.5 | 5.5 | 6.5 |