The NB2000D bottle making machine is a two-cavity PET bottle blowing machine designed for 0.5–2L bottle production. Featuring stable performance, energy-saving infrared heating, and flexible operation, it is an efficient solution for beverage and daily-use plastic bottle manufacturing.

High-efficiency solution for small & medium batch production

NB2000D is a fully automatic blow molding machine compatible with PET and PP materials, and can handle various bottle types from 0.5 liters to 2 liters, including mineral water bottles and carbonated beverage bottles. It will likely continue the series’ advantage of flexible mold cavity configuration, with a production capacity of 1500 bottles per hour for 500 ml bottles, adapting to different production needs.

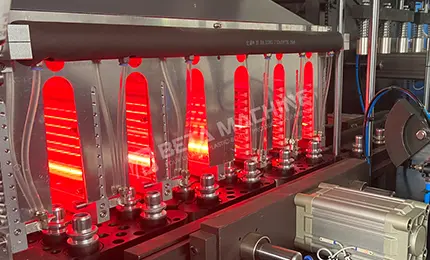

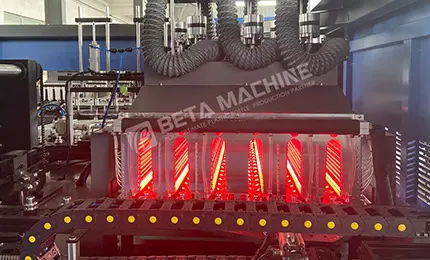

Reasonable design, full automatic control, save power and Labor,Adoptinghigh quality components”Infrared oven heater adopts the quartz lamp to heat the PET tube*Fully automatic process with low investment, high efficiency, quick andsafe operation, easy for trouble -shooting, maintenance and other benefits.

![]()

Delivers stable output with consistent bottle quality.

![]()

Ensures uniform heating while reducing energy consumption.

![]()

Supports different bottle shapes and preform specifications.

![]()

Designed for continuous operation with minimal downtime.

PET water bottles (0.5–2L)

Beverage and juice bottles

Edible oil bottles (small volume)

Daily-use chemical bottles

Household packaging containers

High efficiency, intelligent control, and stable bottle quality

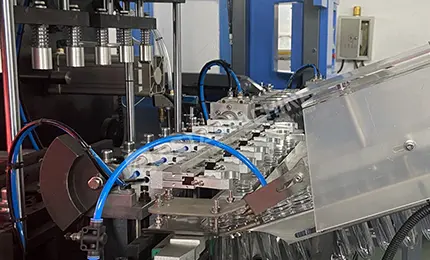

Servo-driven preform feeding and separation system prevents blockage and abrasion, ensuring smooth and continuous operation.

Optimized oven design with adjustable lamps and air-cooling circulation reduces power consumption and ensures uniform heating.

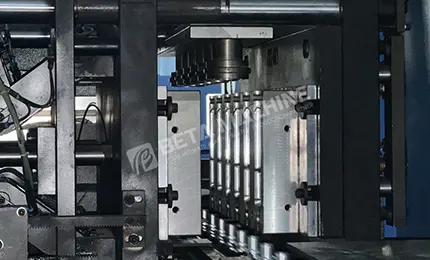

Drawer-type mold structure allows fast bottle shape change, completing mold replacement within one hour.

Advanced servo technology shortens mold-clamping time, improves productivity, and ensures stable bottle quality.

User-friendly interface provides real-time monitoring, production data recording, and fault warning functions.

What bottle size range can the NB2000D produce?

The machine is suitable for PET /PP bottles from 0.5L to 2L.

How many cavities does the NB2000D have?

It is equipped with a 2-cavity mold configuration..

Is the heating system energy efficient?

Yes. The infrared heating system is designed to reduce energy consumption while maintaining stable quality.

Is the NB2000D easy to operate?

Yes. The machine features simple controls and requires minimal operator training..

Is the machine suitable for beverage bottle production?

Yes. It is widely used for water, juice, and other beverage bottles.

| Model No. | Unit | NB-2000D |

| Theoretical output | Pcs/hr | 1500 |

| Container volume | L | 0.5-2 |

| Preform inner diameter | mm | 12-38 |

| Max.bottle diameter | mm | 110 |

| Max.bottle height | mm | 260 |

| Cavity | Pc | 2 |

| Main machine size | M | 1.98×1.65×2.02 |

| Machine weight | T | 2 |

| Feeding machine dimension | M | 1.98×1.35×2.65 |

| Feeding machine weight | T | 2 |

| Max heating power | KW | 20 |

| Installation power | KW | 51 |