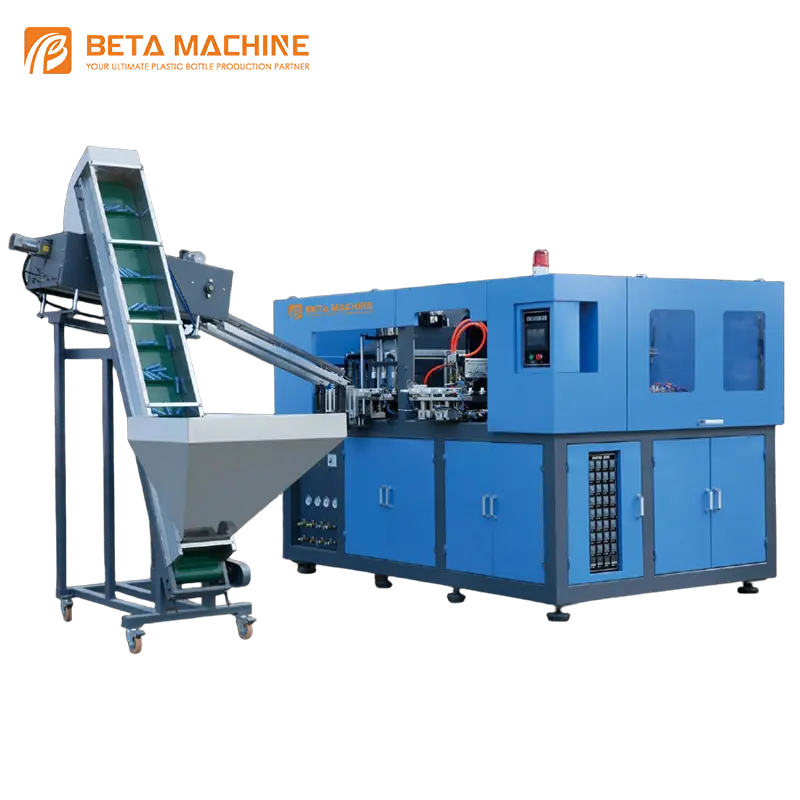

The NB-5000/NB-5000B bottle blowing machine is a 2-cavity automatic blow molding machine designed for producing 3–10L large-volume PET bottles. With stable performance, efficient heating, and intelligent control, it is an ideal solution for water, edible oil, and industrial packaging applications.

High-efficiency solution for small & medium batch production

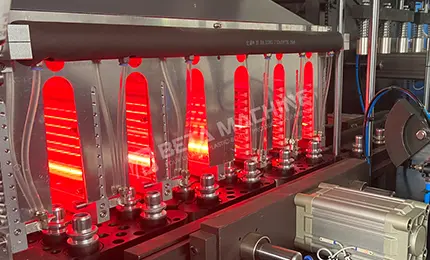

NB-5000 and NB-5000B are high-quality full-automatic blow molding machines designed for medium-to-large capacity PET bottles (3-10L). Boasting theoretical outputs of 500-800 Pcs/hr and 1200-1800 Pcs/hr respectively, they can handle bottles up to 400mm in height and 260mm in diameter. Adopting infrared preheating ovens for preform treatment, the machines achieve consistent and precise bottle forming. With full-automatic control, they significantly cut down labor costs and power consumption. Featuring a reasonable structural design, they offer easy operation, safe use, and convenient maintenance, making them cost-effective choices for medium-to-large volume packaging industries with quick investment returns.

![]()

Designed specifically for large-capacity PET bottles with stable forming.

![]()

User-friendly control system and simplified maintenance design.

![]()

Ensures reliable production efficiency with consistent bottle quality.

![]()

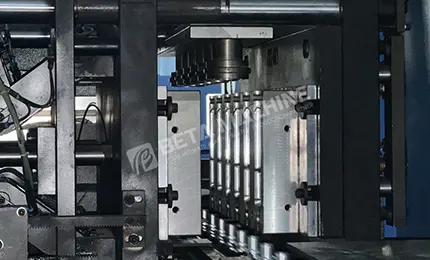

Fully automatic blowing process with reliable mechanical performance.

3–10L PET water bottles

Large edible oil containers

Household chemical bottles

Industrial liquid packaging bottles

Custom large-volume PET containers

High efficiency, intelligent control, and stable bottle quality

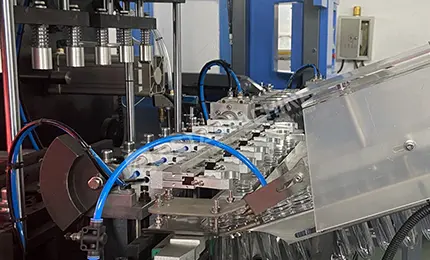

Servo-driven preform feeding and separation system prevents blockage and abrasion, ensuring smooth and continuous operation.

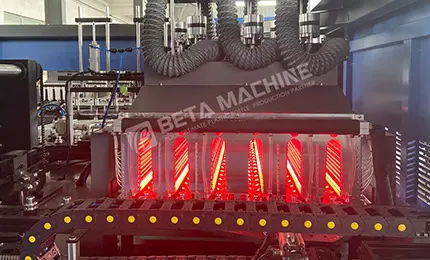

Optimized oven design with adjustable lamps and air-cooling circulation reduces power consumption and ensures uniform heating.

Drawer-type mold structure allows fast bottle shape change, completing mold replacement within one hour.

Advanced servo technology shortens mold-clamping time, improves productivity, and ensures stable bottle quality.

User-friendly interface provides real-time monitoring, production data recording, and fault warning functions.

What bottle size range does the NB-5000/NB-5000B support?

It is designed for PET bottles with a capacity range of 3–10 liters.

How many cavities does this machine have?

The NB-5000/NB-5000B features a 2-cavity mold configuration.

Is the machine fully automatic?

Yes, it operates with a fully automatic bottle blowing process.

What industries is this machine suitable for?

It is widely used in water, edible oil, household chemical, and industrial packaging industries.

Is the machine suitable for customized bottle designs?

Yes. The flexible mold and preform compatibility allow customized bottle production.

| Model No. | Unit | NB-5000 | NB-5000B |

| Theoretical output | Pcs/hr | 500-800 | 1200-1800 |

| Container volume | L | 3-10 | 3-10 |

| Preform inner diameter | mm | 38-65 | 38-65 |

| Max.bottle diameter | mm | 260 | 260 |

| Max.bottle height | mm | 400 | 400 |

| Cavity | Pc | 1 | 2 |

| Main machine size | M | 2.3×1.9×2.1 | 3.2×1.9×2.1 |

| Machine weight | T | 3 | 5 |

| Feeding Machine dimension | M | 2×1.3×2.55 | 2×1.3×2.55 |

| Feeding Machine weight | T | 0.55 | 0.55 |

| Max.heating power | KW | 35 | 50 |

| installation power | KW | 50 | 80 |