1* Increase the injection volume, which is more suitable for the production of multi-cavity products. Tailored according to different requirements, it is more advantageous for the production of packaging, deep cavity and high speed PET preform products

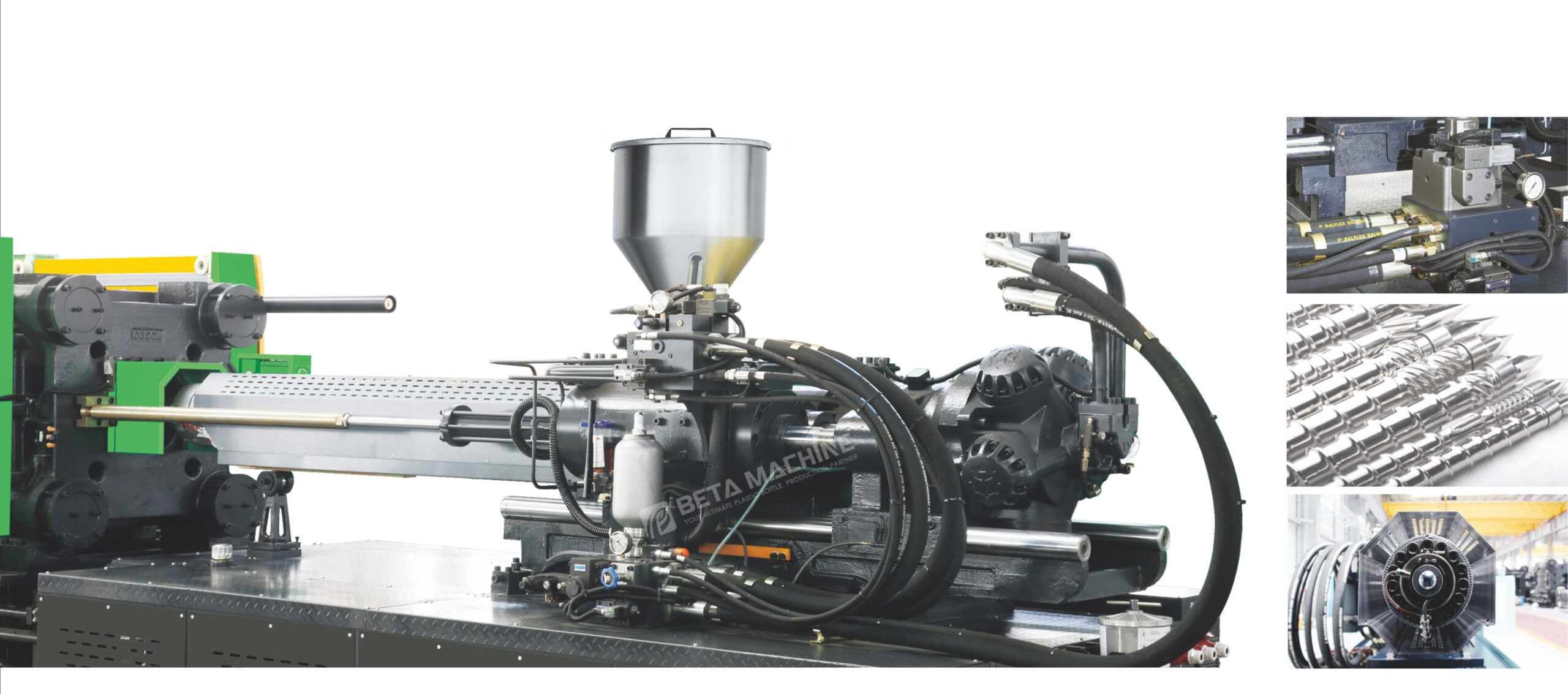

2*PET special screw significantly increases the melting speed and injection volume, reduces the plasticizing temperature, effectively improve the shrinkage of the preform and improve the transparency

3*Increase the thimble force and ejection stroke, which is more suitable for deep cavity PET preform molding

Plastic 5 Gallon Bottle Making Machine Automatic Injection Molding Machine

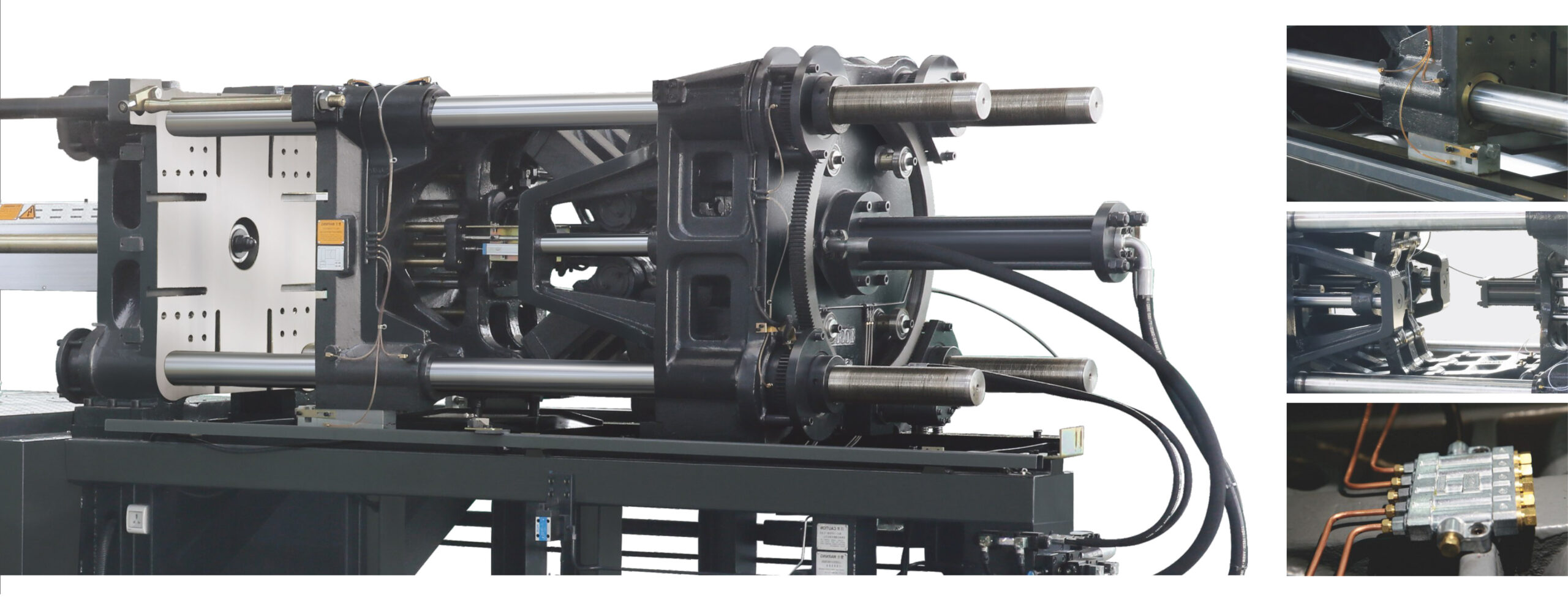

1.Clamping unit

2.Injection Unit

3. Hydraulic Unit

Highly response oil way system, impove the machine speed and also save energy comsumption.

Technical parameters

| Model | Unit | YJPT200 | YJPT230 | YJPT260 |

| Injection Device | 62 | 62 | 72 | |

| Screw Diameter | mm | 24:1 | 24:1 | 24:1 |

| Screw Diameter Ratio | L/D | 814 | 814 | 1300 |

| Theoretical Shot Volume | cm3 | 830 | 830 | 1320 |

| Injection Stroke | g | 270 | 270 | 320 |

| Injection Pressure | Mpa | 131 | 131 | 137 |

| Clamping Unit | ||||

| Clamping Force | KN | 2000 | 2300 | 2600 |

| Togglestroke | mm | 436 | 500 | 560 |

| Space Between Tie-bars | mm*mm | 460*460 | 520*520 | 580*580 |

| Minn-max Mould Thicness | mm | 180-500 | 220-550 | 250-610 |

| Ejection Stroke | mm | 140 | 170 | 170 |

| Ejection Force | KN | 70 | 102 | 102 |

| Other | ||||

| Maximum System Pressure | Mpa | 16 | 16 | 16 |

| Oil Pump System Power(conventional) | KW | 22 | 31.4(Servo) | 48.2(Servo) |

| Heater Power | KW | 22.4 | 22.4 | 35.7 |

| Overall Diameter | m | 6.04*1.46*2.04 | 6.36*1.5*2.16 | 7.18*1.64*2.26 |

| Machine Weight(About) | t | 6 | 7.5 | 8.6 |

| Model | Unit | YJPT360组合式 | YJPT400组合式 | ||

| A2000 | A3000 | A2000 | A3100 | ||

| Injection Device | 82 | 95 | 82 | 95 | |

| Screw Diameter | mm | 24:1 | 24:1 | 24:1 | 24:1 |

| Screw Diameter Ratio | L/D | 2000 | 3100 | 2000 | 3100 |

| Theoretical Shot Volume | cm3 | 2050 | 3160 | 2050 | 3160 |

| Injection Stroke | g | 390 | 440 | 390 | 440 |

| Injection Pressure | Mpa | 132 | 133 | 132 | 133 |

| Clamping Unit | |||||

| Clamping Force | KN | 3600 | 4000 | ||

| Togglestroke | mm | 660 | 730 | ||

| Space Between Tie-bars | mm*mm | 680*680 | 720*720 | ||

| Minn-max Mould Thicness | mm | 280-680 | 280-830 | ||

| Ejection Stroke | mm | 190 | 230 | ||

| Ejection Force | KN | 180 | 180 | ||

| Other | |||||

| Maximum System Pressure | Mpa | 16 | 16 | 16 | 16 |

| Oil Pump System Power(conventional) | KW | 55.5(Servo) | 79.6 (Servo) | 55.5(Servo) | 79.6 (Servo) |

| Heater Power | KW | 49.5 | 60.3 | 49.5 | 60.3 |

| Overall Diameter | m | 8.2*1.86*2.36 | 8.5*1.86*2.36 | 8.9*1.95*2.5 | 9.2*1.95*2.5 |

| Machine Weight(About) | t | 14 | 15.5 | 15 | 16.5 |