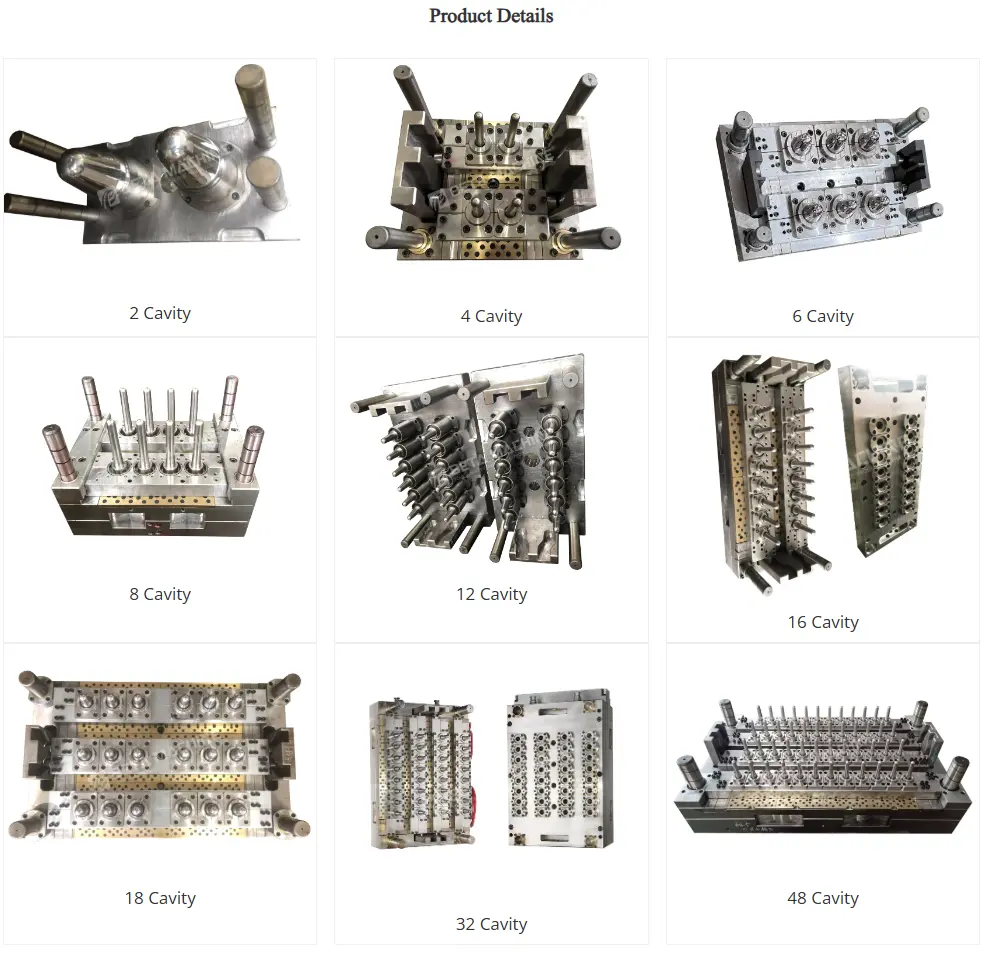

– Advanced mould design technology:

Each cavity self-locks independently and using high precision JAPAN CNC SYSTEM;

To ensure low decent ration & precision of the product; Each mould spare part be inserted with durable parts,which are interchangeable;

In order to improve and achieve high production efficiency, we always design the best cooling system and can match a cooling machine for each mould.

– Advanced & accurated valve hot runner & temperature controller,ensure reliability of production,and high transparency& brightness of product.

– Mould sliding use copper,bottle be achieved food security standard.And mould life guarantee more than 3 million shots.