The NB-2000 series plastic bottle maker is a multiple cavity automatic bottle blow molding machine designed for high-efficiency production of 0.05–2L PET bottles. Featuring servo-controlled systems, energy-saving heating, and intelligent HMI operation, it delivers stable output and consistent bottle quality for beverage and packaging manufacturers.

High-efficiency solution for small & medium batch production

The NB-2000 series blow molding machines include three models—NB-2000, NB-2000C, and NB-2000D—designed to meet different bottle sizes and production requirements.

The NB-2000 offers a high theoretical output of 1,800–2,200 pcs/hour, suitable for containers from 0.05 to 2 L, with 4 cavities, making it ideal for high-speed small bottle production. It supports bottles up to 110 mm in diameter and 365 mm in height, with a maximum heating power of 35 kW.

The NB-2000C is designed for larger containers ranging from 0.5 to 5 L, with flexible 1–2 cavity configuration and an output of 800–1,800 pcs/hour. It can handle bottles up to 200 mm in diameter, making it suitable for wide-mouth or large-volume applications.

The NB-2000D focuses on stable mid-range production, delivering 1,500 pcs/hour for 0.5–2 L bottles with 2 cavities, compact size, and lower machine weight.

All models feature compact layouts, reliable heating systems, and efficient installation power, ensuring stable performance, energy efficiency, and easy operation across diverse production needs.

![]()

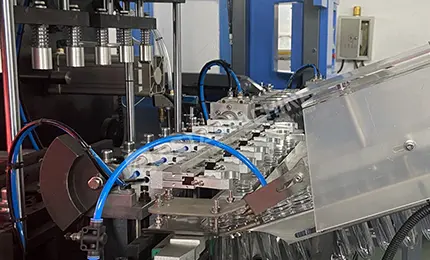

Multiple mold configurations can provide stable production output for medium-scale bottle manufacturing.

![]()

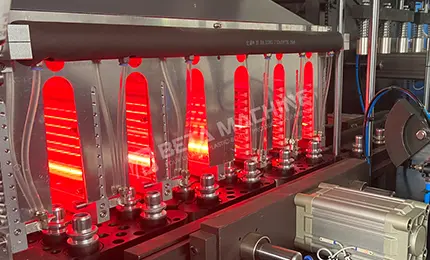

Supports real-time monitoring with manual and automatic modes.

![]()

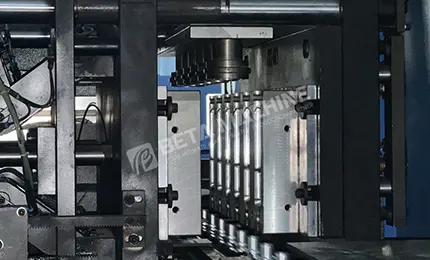

Drawer-type mold structure allows fast mold replacement within one hour.

![]()

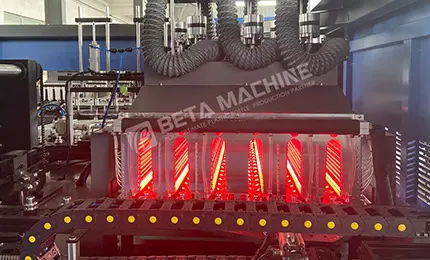

Prevents preform jamming and wear while ensuring stable operation.

PET water bottles (0.05–2L)

Beverage and juice bottles

Carbonated drink bottles

Cosmetic and personal care containers

Small household chemical bottles

High efficiency, intelligent control, and stable bottle quality

Servo-driven preform feeding and separation system prevents blockage and abrasion, ensuring smooth and continuous operation.

Optimized oven design with adjustable lamps and air-cooling circulation reduces power consumption and ensures uniform heating.

Drawer-type mold structure allows fast bottle shape change, completing mold replacement within one hour.

Advanced servo technology shortens mold-clamping time, improves productivity, and ensures stable bottle quality.

User-friendly interface provides real-time monitoring, production data recording, and fault warning functions.

What bottle size range does the NB-2000 series support?

The machine is designed for plastic bottles from 0.05L to 2L.

Is the machine fully automatic?

Yes. It features automatic preform feeding, heating, blowing, and bottle discharge.

How long does it take to change molds?

For bottles with the same neck diameter, mold change can be completed within one hour.

Does the machine reduce downtime during preform shortage?

Yes. The system alarms without stopping the machine, preventing unnecessary downtime.

Is the machine suitable for customized bottle designs?

Yes. The flexible mold and preform compatibility allow customized bottle production.

| Model No. | Unit | NB-2000 | NB-2000C | NB-2000D |

| Theoretical output | Pcs/hr | 1800-2200 | 800-1800 | 1500 |

| Container volume | L | 0.05-2 | 0.5-5 | 0.5-2 |

| Preform inner diameter | mm | 38 | 38-150 | 12-38 |

| Max.bottle diameter | mm | 110 | 200 | 110 |

| Max.bottle height | mm | 365 | 365 | 260 |

| Cavity | Pc | 4 | 1-2 | 2 |

| Main machine size | M | 2×1.8×2 | 1.98×1.65×2.02 | 1.98×1.65×2.02 |

| Machine weight | T | 3 | 3 | 2 |

| Feeding Machine dimension | M | 2×1.3×2.55 | 1.95×1.35×2.65 | 1.95×1.35×2.65 |

| Feeding Machine weight | T | 0.55 | 0.55 | 2 |

| Max.heating power | KW | 35 | 20 | 20 |

| installation power | KW | 50 | 51 | 51 |