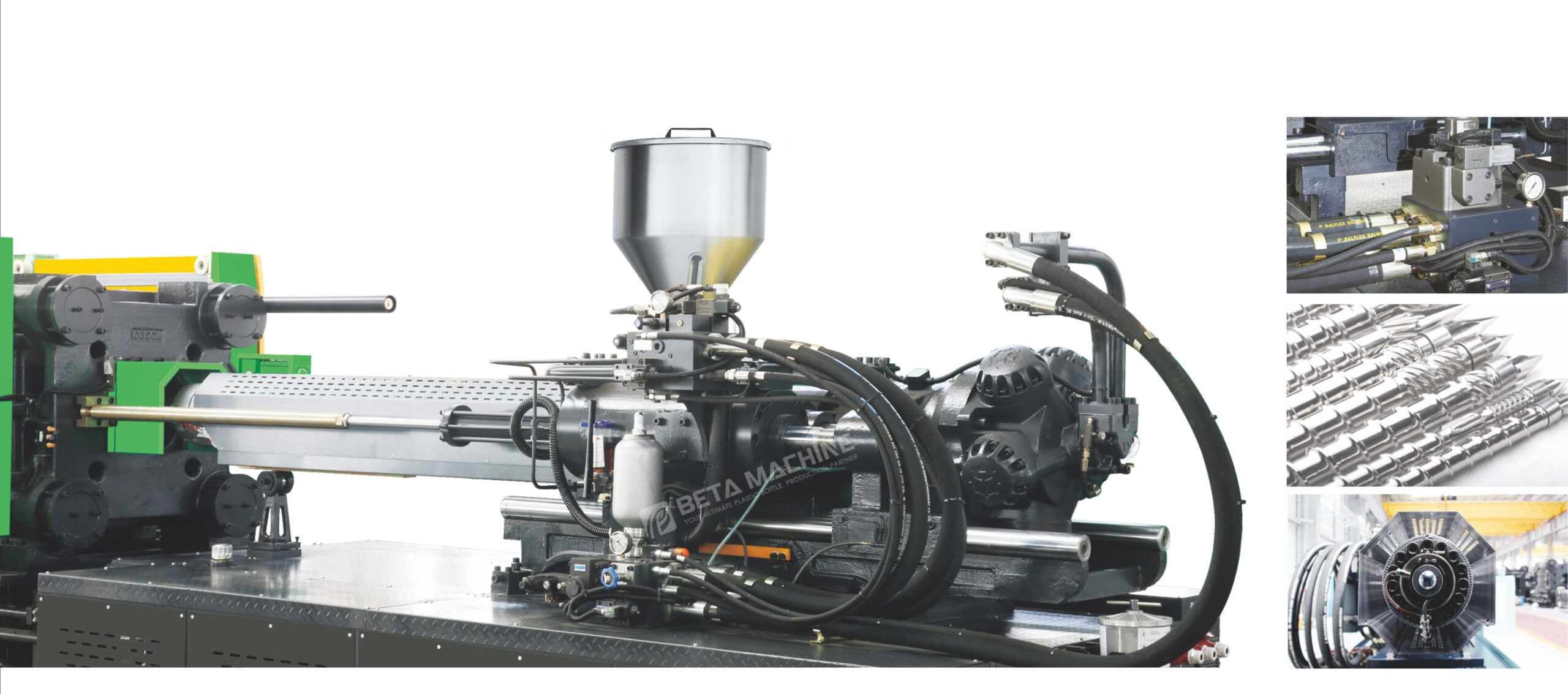

1* Enhance the injection volume, catering to the production of multi-cavity products. Customizable to meet specific requirements, it provides added benefits for manufacturing packaging, deep cavity, and high-speed PET preform products. 2* The PET-specialized screw greatly accelerates the melting speed and injection volume, leading to reduced plasticizing temperature. This effectively enhances preform shrinkage and transparency. 3* Amplify the thimble force and ejection stroke, ideal for deep cavity PET preform molding.

Plastic PET Preform Making Machine Automatic Injection Molding MachineDetailed image

1.High response oil-way system.

1* The utilization of a modularized energy conservation high response oil-way system can effectively enhance the overall speed of the machine, resulting in improved productivity.

2* Additionally, this system is designed to conserve energy, leading to reduced energy consumption during operation.

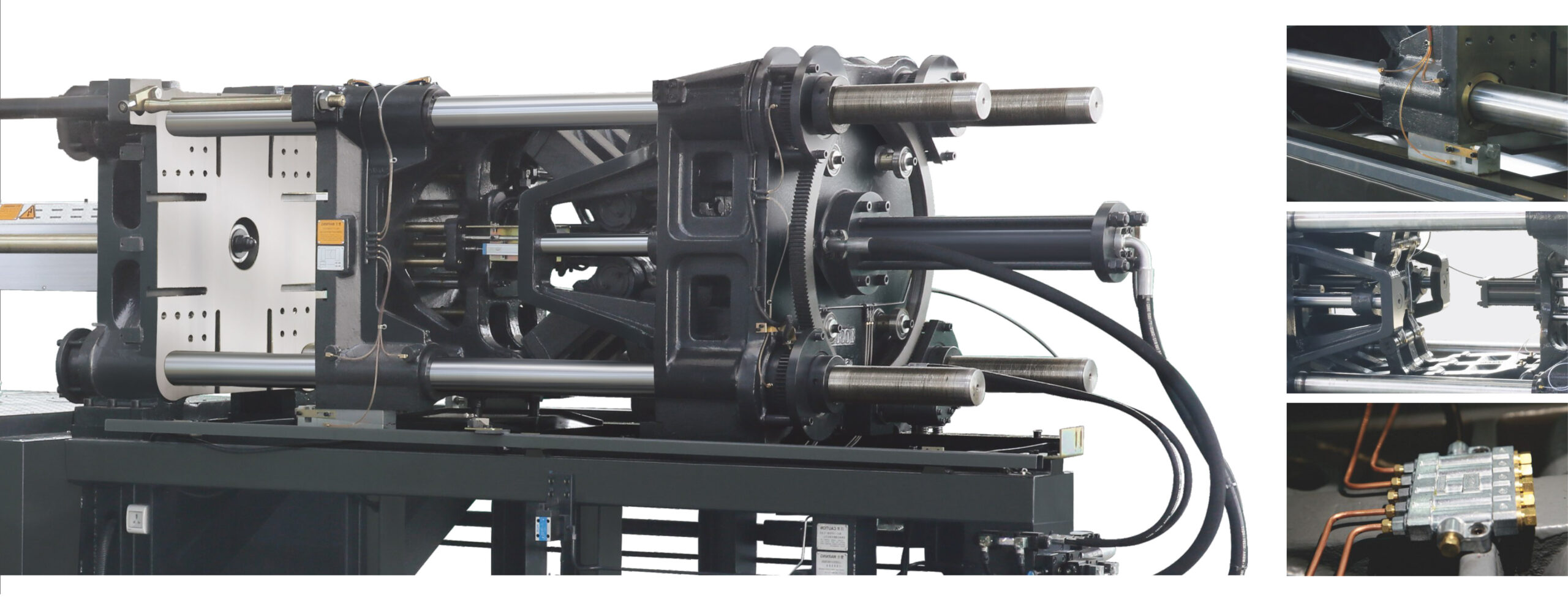

2.Clamping unit

1* The toggle lever of the two-plate clamping unit is centrally aligned, providing optimal balance and stability in operation.

2* The clamping unit is equipped with a closed-loop circulatory lubrication system, ensuring smooth and efficient movement of the two plates.

3* A mold open buffer is incorporated in the design, allowing for controlled and gentle mold opening, minimizing the risk of damage.

4* The clamping unit features a sensitive function for mold protection, utilizing linear guides to ensure precise and reliable protection of the mold, enhancing both customer safety and product quality.

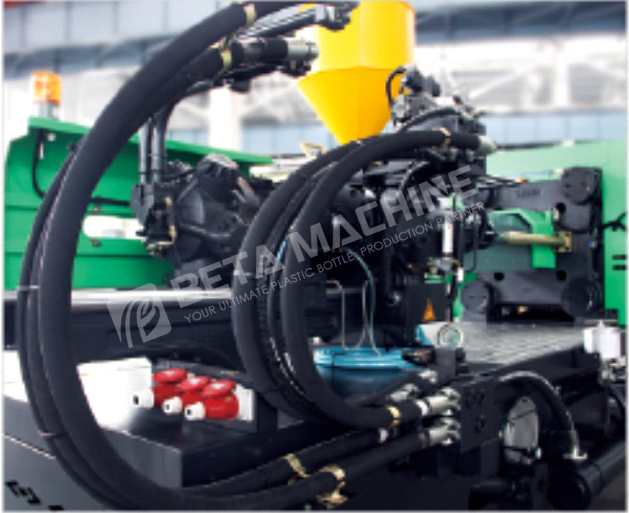

3.Injection Unit

1* The injection unit is optimized to provide the best performance and efficiency.

2* The plasticized barrel and screw assembly are designed to be highly efficient, ensuring optimal plasticization of the material.

3* The BETA system offers unparalleled flexibility, allowing for easy customization and adaptation to various production requirements.

Technical parameters

| Model | Unit | YJPT200 | YJPT230 | YJPT260 |

| Injection Device | 62 | 62 | 72 | |

| Screw Diameter | mm | 24:1 | 24:1 | 24:1 |

| Screw Diameter Ratio | L/D | 814 | 814 | 1300 |

| Theoretical Shot Volume | cm3 | 830 | 830 | 1320 |

| Injection Stroke | g | 270 | 270 | 320 |

| Injection Pressure | Mpa | 131 | 131 | 137 |

| Clamping Unit | ||||

| Clamping Force | KN | 2000 | 2300 | 2600 |

| Togglestroke | mm | 436 | 500 | 560 |

| Space Between Tie-bars | mm*mm | 460*460 | 520*520 | 580*580 |

| Minn-max Mould Thicness | mm | 180-500 | 220-550 | 250-610 |

| Ejection Stroke | mm | 140 | 170 | 170 |

| Ejection Force | KN | 70 | 102 | 102 |

| Other | ||||

| Maximum System Pressure | Mpa | 16 | 16 | 16 |

| Oil Pump System Power(conventional) | KW | 22 | 31.4(Servo) | 48.2(Servo) |

| Heater Power | KW | 22.4 | 22.4 | 35.7 |

| Overall Diameter | m | 6.04*1.46*2.04 | 6.36*1.5*2.16 | 7.18*1.64*2.26 |

| Machine Weight(About) | t | 6 | 7.5 | 8.6 |

| Model | Unit | YJPT360组合式 | YJPT400组合式 | ||

| A2000 | A3000 | A2000 | A3100 | ||

| Injection Device | 82 | 95 | 82 | 95 | |

| Screw Diameter | mm | 24:1 | 24:1 | 24:1 | 24:1 |

| Screw Diameter Ratio | L/D | 2000 | 3100 | 2000 | 3100 |

| Theoretical Shot Volume | cm3 | 2050 | 3160 | 2050 | 3160 |

| Injection Stroke | g | 390 | 440 | 390 | 440 |

| Injection Pressure | Mpa | 132 | 133 | 132 | 133 |

| Clamping Unit | |||||

| Clamping Force | KN | 3600 | 4000 | ||

| Togglestroke | mm | 660 | 730 | ||

| Space Between Tie-bars | mm*mm | 680*680 | 720*720 | ||

| Minn-max Mould Thicness | mm | 280-680 | 280-830 | ||

| Ejection Stroke | mm | 190 | 230 | ||

| Ejection Force | KN | 180 | 180 | ||

| Other | |||||

| Maximum System Pressure | Mpa | 16 | 16 | 16 | 16 |

| Oil Pump System Power(conventional) | KW | 55.5(Servo) | 79.6 (Servo) | 55.5(Servo) | 79.6 (Servo) |

| Heater Power | KW | 49.5 | 60.3 | 49.5 | 60.3 |

| Overall Diameter | m | 8.2*1.86*2.36 | 8.5*1.86*2.36 | 8.9*1.95*2.5 | 9.2*1.95*2.5 |

| Machine Weight(About) | t | 14 | 15.5 | 15 | 16.5 |