1* The injection volume has been enhanced to cater to the production of multi-cavity products. It can be customized to meet specific requirements, making it ideal for manufacturing packaging, deep cavity, and high-speed PET preform products.

Injection Molding Machine For PET Preform

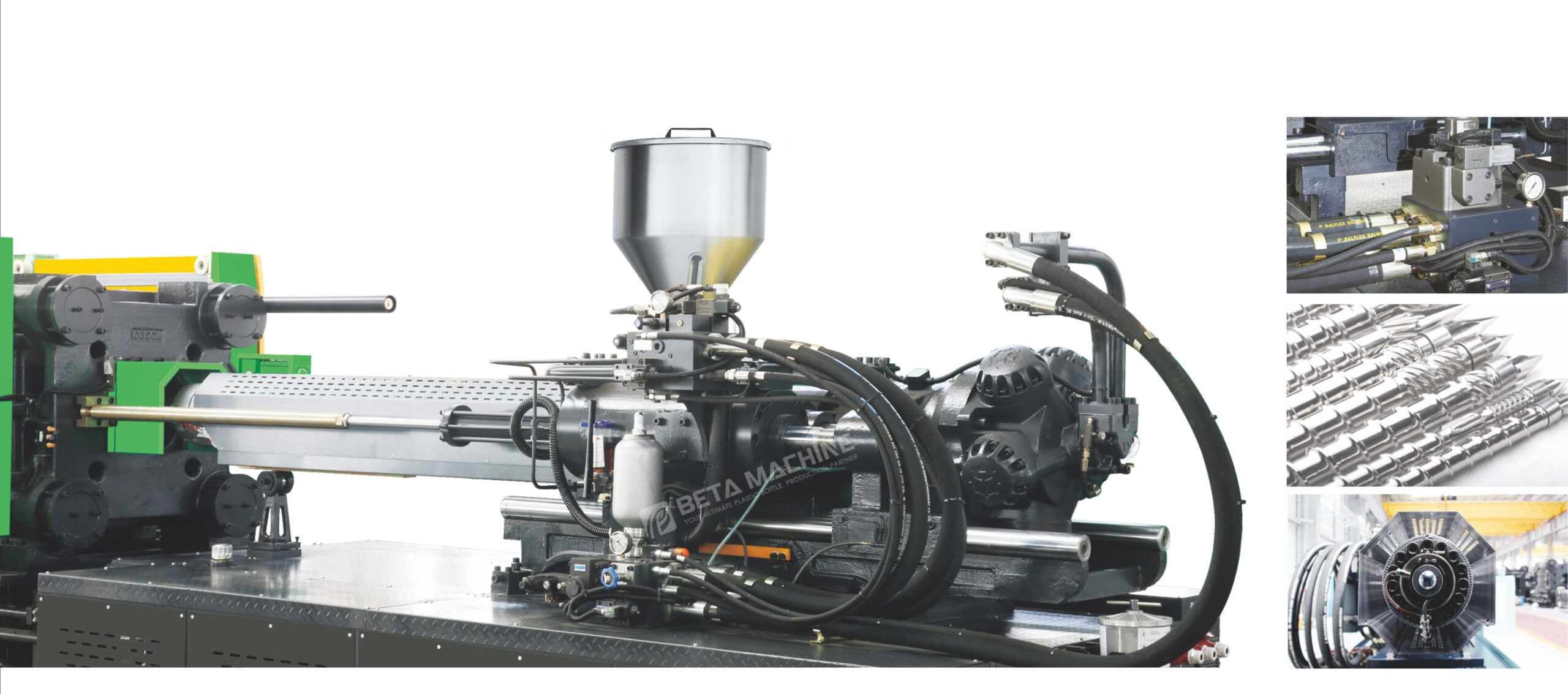

1. The injection volume has been increased to facilitate the production of multi-cavity products. This feature can be tailored to meet specific requirements, making it ideal for manufacturing packaging, deep-cavity, and high-speed PET preform products.

2. The PET special screw significantly increases the melting speed and injection volume, while reducing the plasticizing temperature. This effectively enhances the shrinkage of the preform and improves its transparency.

3. The thimble force and ejection stroke have been increased, making it more suitable for molding deep-cavity PET preforms.

Welcome to China Molding Machine Supplier, a leading provider of advanced injection molding solutions. Our Injection Molding Machine for PET Preforms is specifically designed to produce high-quality PET preforms for applications in the beverage, food, pharmaceutical, and cosmetic industries. This machine combines precision engineering, energy efficiency, and advanced control systems to deliver consistent and high-quality results.

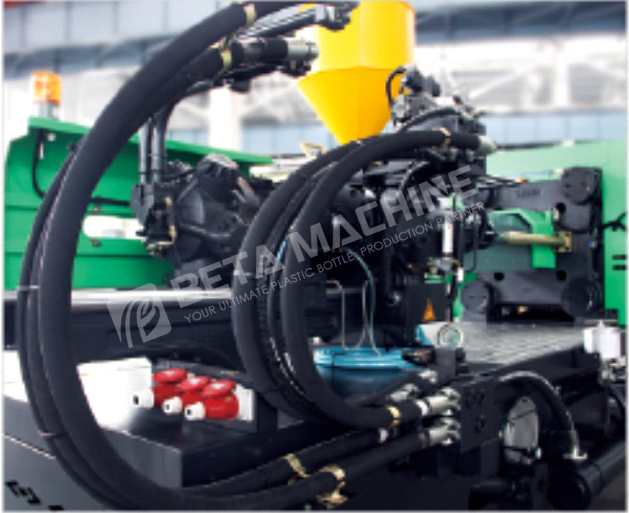

1.High response oil-way system.

Modularized energy-saving and responsive oil-way system can enhance the overall machine speed and reduce energy consumption.

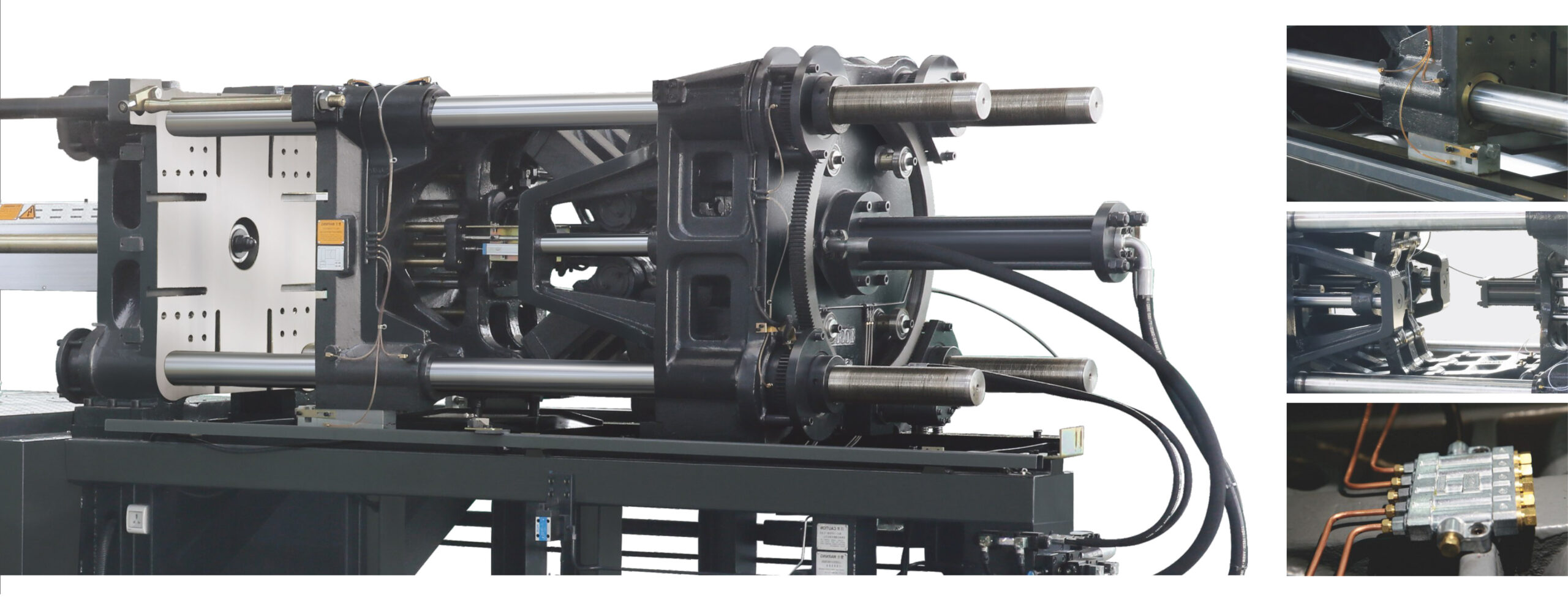

2.Clamping unit

The clamping unit with two plates has a design that is compact and saves space. Additionally, the two plates are completely frictionless, ensuring that the templates are parallel and the molds are highly protected through linear guides. This provides the highest level of safety for customers and guarantees the best quality products. Other features of this unit include a toggle lever that is centrally aligned to ensure precise operation, a closed-loop circulatory lubrication system, a mold open buffer for smooth operation, and a highly sensitive mold protection function.

3.Injection Unit

1. Optimize the injection unit.

2. Use an efficient plasticized barrel and screw assembly.

3. The BETA offers ultimate flexibility.

Technical parameters

| Model | Unit | YJPT200 | YJPT230 | YJPT260 |

| Injection Device | 62 | 62 | 72 | |

| Screw Diameter | mm | 24:1 | 24:1 | 24:1 |

| Screw Diameter Ratio | L/D | 814 | 814 | 1300 |

| Theoretical Shot Volume | cm3 | 830 | 830 | 1320 |

| Injection Stroke | g | 270 | 270 | 320 |

| Injection Pressure | Mpa | 131 | 131 | 137 |

| Clamping Unit | ||||

| Clamping Force | KN | 2000 | 2300 | 2600 |

| Togglestroke | mm | 436 | 500 | 560 |

| Space Between Tie-bars | mm*mm | 460*460 | 520*520 | 580*580 |

| Minn-max Mould Thicness | mm | 180-500 | 220-550 | 250-610 |

| Ejection Stroke | mm | 140 | 170 | 170 |

| Ejection Force | KN | 70 | 102 | 102 |

| Other | ||||

| Maximum System Pressure | Mpa | 16 | 16 | 16 |

| Oil Pump System Power(conventional) | KW | 22 | 31.4(Servo) | 48.2(Servo) |

| Heater Power | KW | 22.4 | 22.4 | 35.7 |

| Overall Diameter | m | 6.04*1.46*2.04 | 6.36*1.5*2.16 | 7.18*1.64*2.26 |

| Machine Weight(About) | t | 6 | 7.5 | 8.6 |

| Model | Unit | YJPT360组合式 | YJPT400组合式 | ||

| A2000 | A3000 | A2000 | A3100 | ||

| Injection Device | 82 | 95 | 82 | 95 | |

| Screw Diameter | mm | 24:1 | 24:1 | 24:1 | 24:1 |

| Screw Diameter Ratio | L/D | 2000 | 3100 | 2000 | 3100 |

| Theoretical Shot Volume | cm3 | 2050 | 3160 | 2050 | 3160 |

| Injection Stroke | g | 390 | 440 | 390 | 440 |

| Injection Pressure | Mpa | 132 | 133 | 132 | 133 |

| Clamping Unit | |||||

| Clamping Force | KN | 3600 | 4000 | ||

| Togglestroke | mm | 660 | 730 | ||

| Space Between Tie-bars | mm*mm | 680*680 | 720*720 | ||

| Minn-max Mould Thicness | mm | 280-680 | 280-830 | ||

| Ejection Stroke | mm | 190 | 230 | ||

| Ejection Force | KN | 180 | 180 | ||

| Other | |||||

| Maximum System Pressure | Mpa | 16 | 16 | 16 | 16 |

| Oil Pump System Power(conventional) | KW | 55.5(Servo) | 79.6 (Servo) | 55.5(Servo) | 79.6 (Servo) |

| Heater Power | KW | 49.5 | 60.3 | 49.5 | 60.3 |

| Overall Diameter | m | 8.2*1.86*2.36 | 8.5*1.86*2.36 | 8.9*1.95*2.5 | 9.2*1.95*2.5 |

| Machine Weight(About) | t | 14 | 15.5 | 15 | 16.5 |