1* The injection volume has been enhanced to cater to the production of multi-cavity products. It can be customized to meet specific requirements, making it ideal for manufacturing packaging, deep cavity, and high-speed PET preform products.

Machine For Plastic Caps For Bottles Automatic Injection Molding Machine

PET series preform injection molding machine combines advanced technology at home and abroad, and has the advantages of energy saving, environmental protection, stability, reliability and high precision. The machine has complete specifications and is suitable for a variety of different preforms; it is extremely cost- effective and can create a better return on investment and an better experience for customers!

Welcome to China Molding Machine Supplier, a leading provider of high-quality injection molding machines. Our Automatic Caps Bottles Injection Molding Machine is designed to efficiently produce plastic bottle caps for various industries, including beverages, pharmaceuticals, and cosmetics. This machine combines advanced technology with user-friendly features to deliver high precision and productivity.

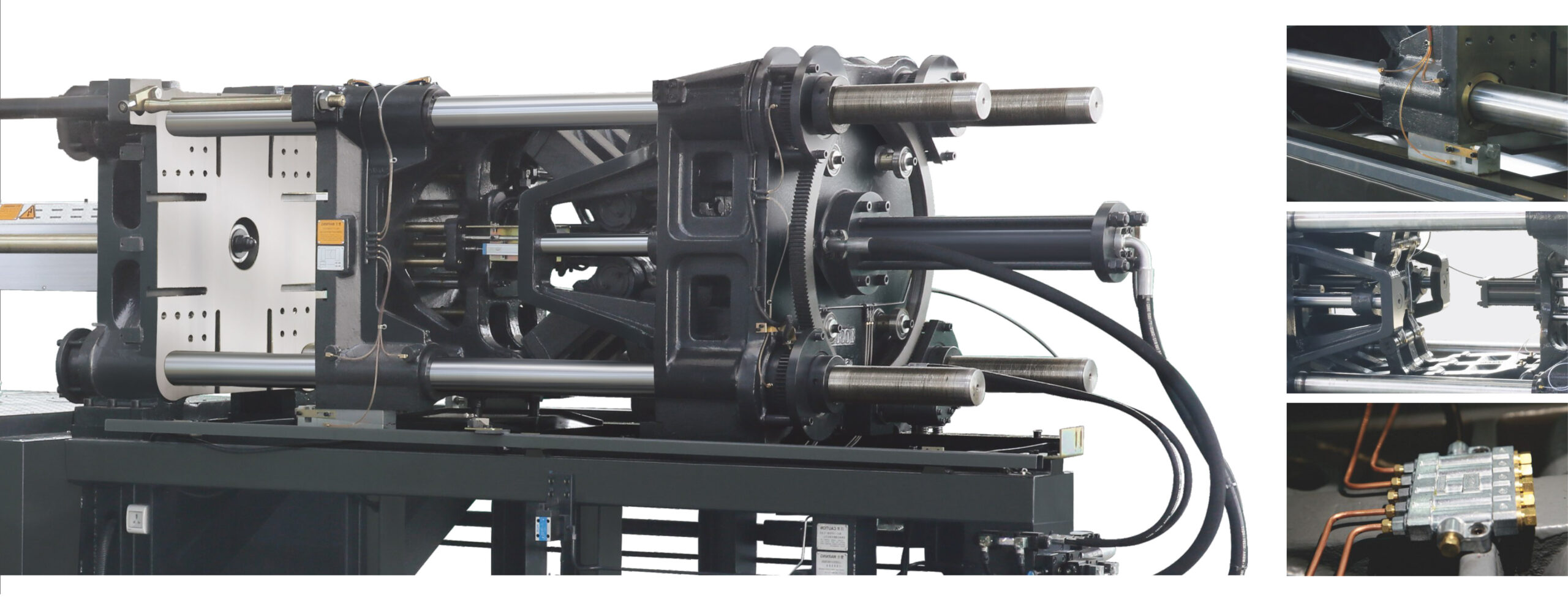

1.Clamping unit

The compact and space-efficient design of the two-plate clamping unit is complemented by its frictionless operation, guaranteeing optimal template parallelism and precise mold protection through linear guides. These features not only ensure maximum customer safety but also enhance product quality.

1.The toggle lever is centrally aligned, promoting balanced force distribution.

2.The closed-loop circulatory lubrication system ensures efficient and consistent lubrication.

3.A buffer is incorporated for mold opening, preventing abrupt movements and minimizing potential damage.

4.The system includes a sensitive function for mold protection, providing an extra layer of safety during operation.

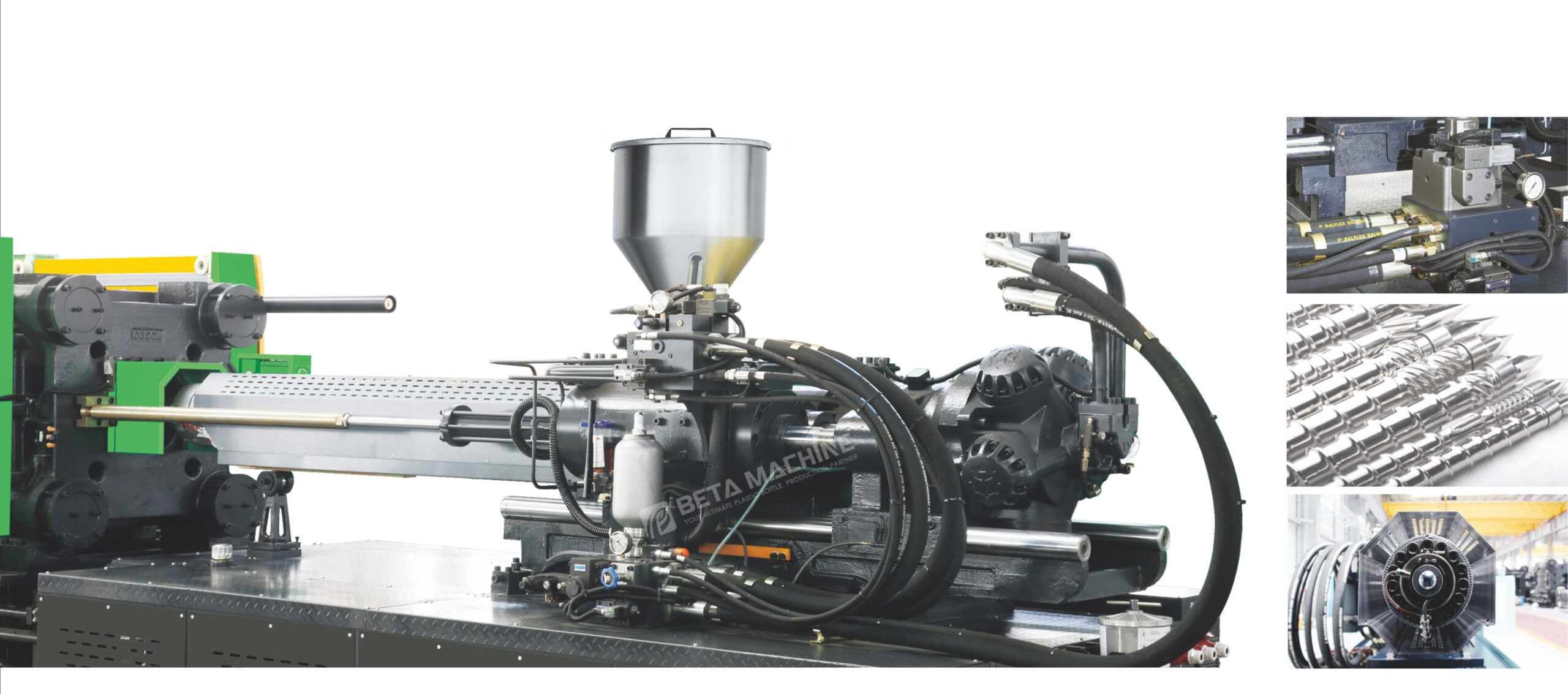

2.Injection Unit

1.The injection unit has been optimized to maximize performance and efficiency.

2.The plasticized barrel and screw assembly have been designed to operate efficiently, ensuring optimal plasticization of the material.

3.The BETA system offers unparalleled flexibility, allowing for a wide range of customization options to meet specific production needs.

3. Applications

Technical parameters

| Model | Unit | YJPT200 | YJPT230 | YJPT260 |

| Injection Device | 62 | 62 | 72 | |

| Screw Diameter | mm | 24:1 | 24:1 | 24:1 |

| Screw Diameter Ratio | L/D | 814 | 814 | 1300 |

| Theoretical Shot Volume | cm3 | 830 | 830 | 1320 |

| Injection Stroke | g | 270 | 270 | 320 |

| Injection Pressure | Mpa | 131 | 131 | 137 |

| Clamping Unit | ||||

| Clamping Force | KN | 2000 | 2300 | 2600 |

| Togglestroke | mm | 436 | 500 | 560 |

| Space Between Tie-bars | mm*mm | 460*460 | 520*520 | 580*580 |

| Minn-max Mould Thicness | mm | 180-500 | 220-550 | 250-610 |

| Ejection Stroke | mm | 140 | 170 | 170 |

| Ejection Force | KN | 70 | 102 | 102 |

| Other | ||||

| Maximum System Pressure | Mpa | 16 | 16 | 16 |

| Oil Pump System Power(conventional) | KW | 22 | 31.4(Servo) | 48.2(Servo) |

| Heater Power | KW | 22.4 | 22.4 | 35.7 |

| Overall Diameter | m | 6.04*1.46*2.04 | 6.36*1.5*2.16 | 7.18*1.64*2.26 |

| Machine Weight(About) | t | 6 | 7.5 | 8.6 |

| Model | Unit | YJPT360组合式 | YJPT400组合式 | ||

| A2000 | A3000 | A2000 | A3100 | ||

| Injection Device | 82 | 95 | 82 | 95 | |

| Screw Diameter | mm | 24:1 | 24:1 | 24:1 | 24:1 |

| Screw Diameter Ratio | L/D | 2000 | 3100 | 2000 | 3100 |

| Theoretical Shot Volume | cm3 | 2050 | 3160 | 2050 | 3160 |

| Injection Stroke | g | 390 | 440 | 390 | 440 |

| Injection Pressure | Mpa | 132 | 133 | 132 | 133 |

| Clamping Unit | |||||

| Clamping Force | KN | 3600 | 4000 | ||

| Togglestroke | mm | 660 | 730 | ||

| Space Between Tie-bars | mm*mm | 680*680 | 720*720 | ||

| Minn-max Mould Thicness | mm | 280-680 | 280-830 | ||

| Ejection Stroke | mm | 190 | 230 | ||

| Ejection Force | KN | 180 | 180 | ||

| Other | |||||

| Maximum System Pressure | Mpa | 16 | 16 | 16 | 16 |

| Oil Pump System Power(conventional) | KW | 55.5(Servo) | 79.6 (Servo) | 55.5(Servo) | 79.6 (Servo) |

| Heater Power | KW | 49.5 | 60.3 | 49.5 | 60.3 |

| Overall Diameter | m | 8.2*1.86*2.36 | 8.5*1.86*2.36 | 8.9*1.95*2.5 | 9.2*1.95*2.5 |

| Machine Weight(About) | t | 14 | 15.5 | 15 | 16.5 |